Compact Jaw Crusher Alternative to Maximize Your Material Profits

Turn your concrete, asphalt, and rock into money.

Turn your concrete, asphalt, and rock into money.

Turn your concrete, asphalt, and rock into money.

There is the right tool for every job. Compact impact crushers are a good alternative for contractors who want to produce spec materials and grow their business faster.

Your job and material requirements change. RUBBLE MASTER Compact Crusher can produce a gradable and compactable spec base material or a non-spec material, so that you can tackle more jobs and grow your business faster.

Impactors produce a finished product with a superior cuboid shape and gradation. Your will never fail to impress your clients, so that your material is accepted at more jobs and you can charge a premium for your product.

Finding more jobs and increasing the machine's utilization will help you to grow your business faster.

A compact jaw crusher without a screening plant will...

Turn your materials into money with refined machines that maximize profits and minimize downtime.

RUBBLE MASTER compact crushers provide the best throughput capacity in their class without sacrificing mobility.

Operating a crusher doesn’t have to require years of experience. Our crushers make material processing easier than ever, so you can put any operator on your RUBBLE MASTER with confidence.

Aggregate equipment is bulky, heavy, and difficult to move. RUBBLE MASTER machines are designed from scratch with mobility in mind, so you get the freedom to move anywhere and save transport costs.

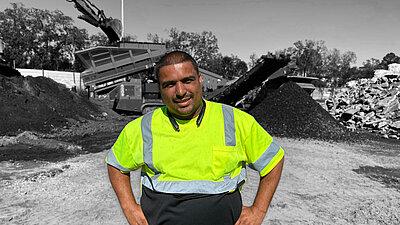

"We used a compact jaw crusher for recycling concrete and struggled with inconsistent material that was hard to grade, and difficult to sell."

Nick Hooper, Dependable Demolition

A common argument for a compact jaw crusher is your wear cost. Jaw type crushers experience less wear but you can't get anywhere near the reduction ratio of an impact crusher. Without a high reduction ratio you can't produce enough fines to meet spec. Additionally, it will be almost impossible to process asphalt when it is warm outside.

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not hauling material or fixing your machines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

At RUBBLE MASTER we understand your challenges starting your own material processing profit center. For more than 30 years, we’ve established ourselves as the world’s leading compact crushing brand helping the most cutting-edge contractors to turn their materials into money.

Don’t just take our word for it.

"We have tried bigger machines than ours with the same output as our RUBBLE MASTER."

Calvin Schouten & Wiebren deBoer, Schouten Excavating

"I started with a RM 70GO! which helped me to grow my material business. At first, I wanted to crush my own material but since then I've started to do contract crushing as well."

Danny Salomon, Dial 3 Dumpster

"I love the machine's compact design and the ability to produce my own ¾ inch minus material that I can reuse on my jobs. "

Alfred Lauzon, Northern Paving

In this FREE 45-minute masterclass, you’ll learn from an experienced panel of contractors just like you who own crushers. RUBBLE MASTER has helped thousands of contractors get started with material processing, boost their profits, and grow their business.

Will you be next?