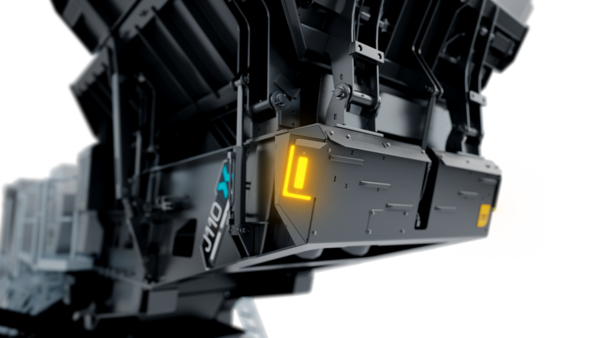

RM J110X

Mobile Jaw Crusher

Dominate the Jobsite With

a Mobile Jaw Crusher that Takes the Brunt

The Heaviest Jaw in Its Class

The heart of the machine comes with extra strength to keep you crushing in the toughest of applications.

A New Experience Operating a Mobile Crusher

Settings and maintenance are easy so you can put any operator on our machine with confidence.

Lowest Operating Costs Through Latest Hydraulic Technologies

Consumes less hydraulic fluid, requires fewer change intervals, and therefore more cost-efficient to maintain.

All The Extra Strength in All The Right Places

The RM J110X makes light work out of hard rock and heavily reinforced concrete. It is the heaviest jaw in the industry. This 44” x 28” (1,100 x 700 mm) hydraulic jaw doesn’t cut corners so

that you can feed bigger pieces. A 10% deeper jaw box gives you more crushing action.

Don’t Get Stuck.

Reverse Crushing Keeps You Crushing.

Crush difficult materials or unblock your crusher with ease.

Extra Safety with Tramp Iron

Hydraulic relief system opens a staggering 12½“ (320 mm)

Smooth Material Discharge

Material deflection plate, impact bed, and a reliable skirting protection extend the lifetime of your conveyor.

Astonishing Usability.

Advanced Crusher Control.

Get more of what people love about RUBBLE MASTER: ease of operation paired with more clarity and simple maintenance procedures so you can maximize your uptime and put more product on the ground. Best of all, the RM XSMART Telemetry is included, so you know you got the most out of your machine.

An All-Around Crusher Control System to Optimize Throughput and Keep Crushing

Automatic feed control. Jaw-level sensor. Overload protection. Conveyor belt slippage detection.

Adjust your Closed-Site Setting with the Touch of a Button While Crushing

Extra wide 1¾“-7“ (45 mm – 175 mm) CSS range.

Enjoy the Comfort & Safety of Your Cab

Start, stop or adjust your feeder speed, adjust your closed side setting whilst crushing, and lower the main conveyor from your radio control

12.5" Information PanelX

Get more clarity and finetune your machine for a comfortable and consistent feed rate.

Performance IndicatorX

The performance indicator helps you hit the feed rate sweet spot to maximize your production intuitively.

- 1 bar = < 25% utilization

- 2 bars = < 50% utilization

- 3 bars = 100% utilization

All 3 lights flashing indicate the crusher is in an overload situation.

Status LightingX

Status lights show the condition of the machine.

- Green - in operation / ready to crush

- Yellow - not ready to be fed or the machine is being moved

- Red - not ready because there is an issue

The Latest Innovations to Get More Bang for Your Buck

The RM J110X unites a 375 HP diesel engine with the latest hydraulic technology for an unrivaled combination of performance and efficiency. Change consumables faster and more efficiently to maximize your profit per manhour.

Cut Your Hydraulic Oil Costs

Change less hydraulic fluid less often.

80 gal (300 liters) only.

CAT Diesel-Engine

AProven Powerhouse

The engine, radiator, water hoses, and after-treatment are all mounted on the same frame and covered under CAT warranty.

Ground Level Drainage Points and Fueling

Accessibility second to none.

Reduce The Burden.

Do the Things you Want to Keep Doing

At RUBBLE MASTER we understand that you want to keep crushing. To get more done, we cut setup and maintenance time. Instead of wasting manhours and running in circles you can focus on dominating your jobsite.

Getting Stuck Doesn’t Mean You Shovel

Start the crusher under load. Eliminate a safety hazard without leaving your cab.

Cut Changing your Fixed Jaw to Hours

Quick-release wedges, convenient hooks, & a built-in hydraulic pusher rod makes light work out of a hard job.

Say Goodbye to Performing Stunts When Putting in Safety Pins

Hydraulic folding & self-locking hopper walls from the ground.

“Starting with a blank canvas allows you to forge a machine that unites the best solutions in the industry with RUBBLE MASTER’s ease of use.”

Martin Wheatley, product manager, jaw crusher

Video Gallery

RM J110X Specs

| Capacity | 450 tph 496 TPH |

| Inlet opening | 1,100 x 700 mm 44" x 28" |

| Crusher unit | Single toggle jaw crusher Single toggle jaw crusher |

| Drive | Diesel-hydraulic Diesel-hydraulic |

| Engine | 250kW CAT Tier 4F 375 HP CAT Tier 4F |

| Feed unit | 6.15 m³ 8 yd³ |

| Feed unit (extended) | 12 m³ 15.5 yd³ |

| Prescreen Grizzly (standard) | 2,000 x 1,080 mm 6’ 6” x 3’ 6” |

| Belt width | 1,200 mm 47¼“ inch |

| Stockpile height | 3,900 mm 12‘ 9“ |

| Weight | 52,000 kg 114,640 lbs |

| Transport dimension | 14.7 m x 2.85 m x 3.4 m 48‘3“ x 9‘5“ x 11‘2“ |

RM XSMART Telemetry

RM XSMART Telemetry

|

Purchase Your Crusher the Easy Way

RUBBLE MASTER Finance provides leasing and financing solutions to keep your business productive, efficient, and competitive within the industry by offering a suite of financing products that can be customized to meet the most complex budgetary needs

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.