Make more money per produced ton with diesel-electric crushers

Electrification is the Future of Construction Equipment

[ FREE WEBINAR ] Cut Your Costs Per Ton: Impact Crushers for Natural Rock? → February 19 - 9 am EST → Join the webinar and see where the real savings are.

At RUBBLE MASTER we look at crushing in its entirety. We understand you can't afford to be down or waste money on high operating costs. Our diesel-electric drives maximize your profits while minimizing downtime.

compared to traditional diesel-hydraulic crushers.

RUBBLE MASTER crushers operate a small hydraulic system for auxiliary functions only.

Electric drives maintain its performance in the harshest conditions and over time.

If you don't use an efficient diesel-electric drive in your crusher, you...

Reduce losses. Increase efficiencies. Make more money.

The direction of all conveyor belts can be reversed by the press of a button to undo a blockage or to adjust your belt tracking.

Run conveyor belts individually for maintenance or to clear a belt before transport without firing up the entire machine.

No overheating in the summer time and no heating up in winter.

Lower risk of damaging a conveyor belt or other components if something gets wedged in.

Surprisingly quiet crusher.

Electric errors are easy to trace and repair.

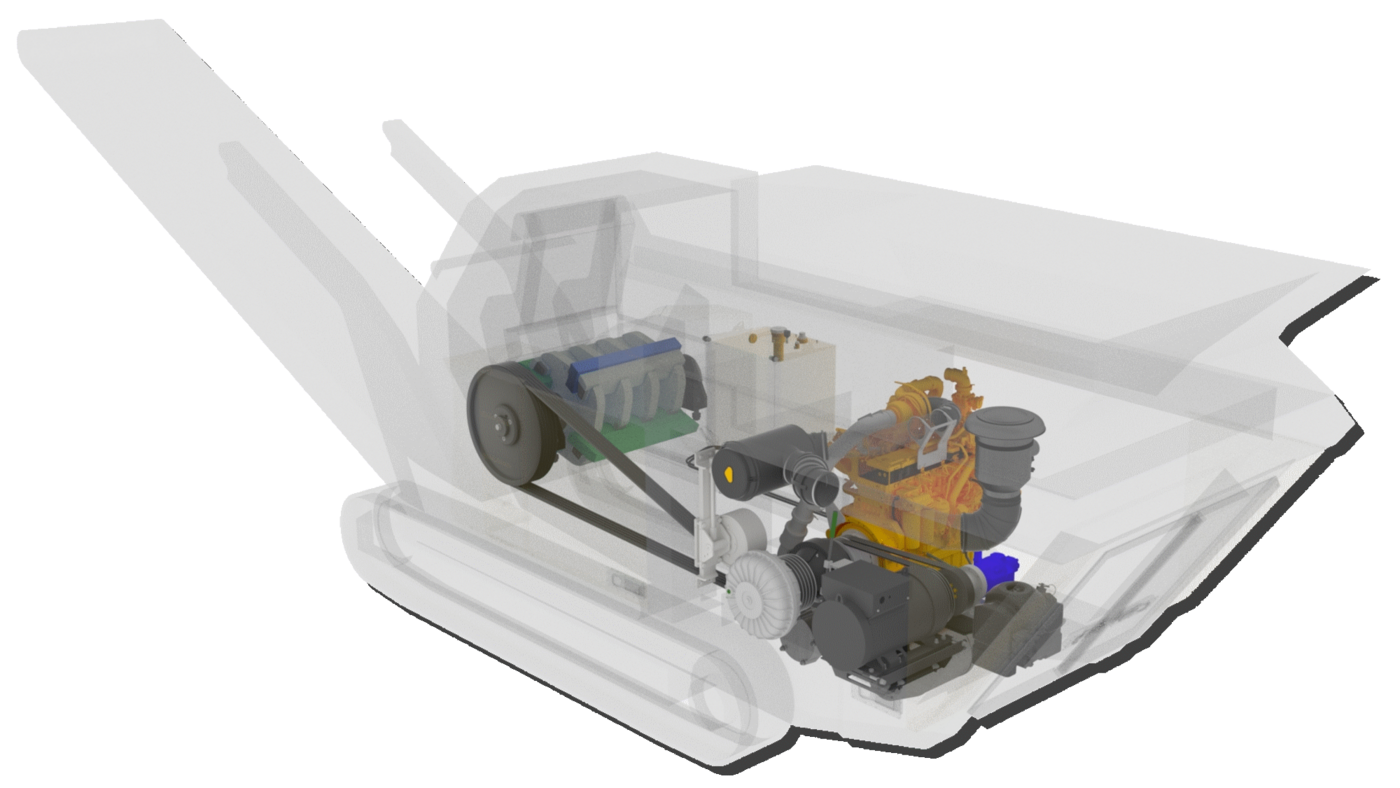

The diesel-engine runs a generator to produce the power for all auxiliary drives (such as discharge & transfer conveyors). The impact crusher rotor is directly driven by the diesel-engine via a v-belts delivering the full power of the diesel engine. A manual twin-disc clutch engages and disengages the rotor and the crushing operation. A hydraulic coupling is used for a soft start of the rotor.

Electric powered auxiliary drives

Crusher rotor is directly driven by the diesel engine via v-belts.

Manual twin-disc clutch to engage/disengage the crusher. Soft start via a hydraulic coupling.

Small hydraulic system to operate cylinders and tracking the machine.

Really, there are not a lot. The biggest flex of any hydraulic plant over an electric plant is the easy stepless adjustment of motor speeds (e.g. feed speed, rotor speed, conveyor belts) through a simple flow valve. Electric drives require additional power electronics to get this accomplished. Our crushers can both adjust the rotor and the feed speed.

Many diesel-hydraulic impact crushers struggle with crushing asphalt continuously because of asphalt dust building up inside the radiators leading to overheating issues and loss of power. Diesel-electric crushers require less cooling and can use smaller radiators, so that you face less maintenance and downtime.

Smooth material flow. Less dust build-up. Easy to clean.

The radiator's location is not directly exposed to dust.

Radiator swings out 90° for cleaning.

(except RM 70GO! 2.0)

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not hauling material or fixing your machines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

Noisy construction machinery result in complaints by the neighbours and the DEP or Ministry of Environment. The highly-efficient diesel-electric drive allows for smaller and less noisy diesel-engines, so that you can run without getting distracted and get the job done. It also increases safety because you can communicate with your crew more easily while the machine is running.

Innovation is part of RUBBLE MASTER's DNA. We strive to make our machines more efficient, user-friendly, and safe every day, so that you can dominate your jobsite and grow your business.

Aggregate producers world-wide use electric power to run their stationary- or semi-mobile equipment. Why would you run hydraulics on a mobile crushing plant?

RUBBLE MASTER diesel-electric drives provide more power to run an additional screening plant (such as the RM CS-Series Compact Screens), water pump for a dust suppression, or stacking conveyor

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.