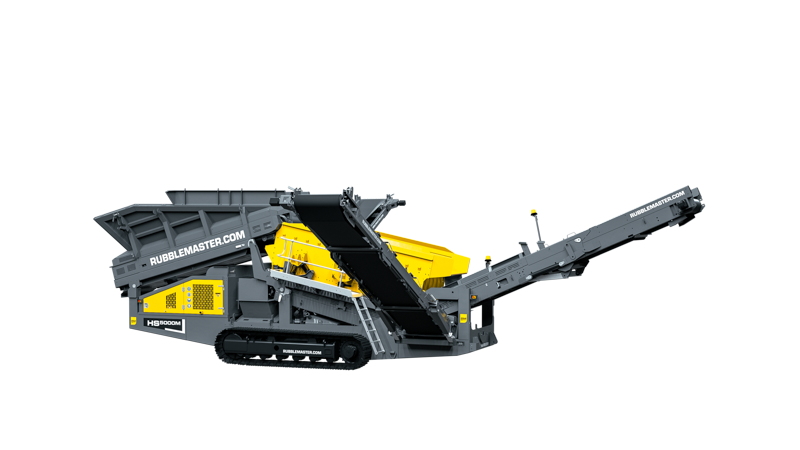

RM HS5000M

Mobile Scalping Screen

Mobile Scalping Screen

The RM HS5000M mobile scalping screen has been designed for maximum productivity and superior screening efficiency. It can be used for heavy duty scalping as well as precision screening applications. The highly aggressive screen can cater for a wide variety of applications and materials such as topsoil, aggregates, sand & gravel, excavated C&D waste, mulch, asphalt millings and more.

3-Way Split

3 finished products

One machine, multiple applications

Process C&D waste, asphalt, millings, sand & gravel,soil, mulch and more.

Easy access

Hydraulic lifting screen-box to change screen media conveniently.

Adjustable conveyor speeds

Feed conveyor and discharge conveyor speeds can be adjusted easily to achieve top performance.

Multiple settings

With a wide selection of screen media and screen-box adjustments operators can customize the scalping screen to suit your exact application.

Optional 2-Way Split

Produce only 2 products instead of 3.

Move Anywhere, Anytime

The RM HS5000M provides excellent mobility on the road and on the job. Hydraulic folding conveyor allows for easy and quick setup. Over top folding side conveyors ensure conveyor belt longevity and ease of setup.

Easy setup

One operator can set up the screen without the need of any special hand tools.

Fast setup

15 minutes from trailer to screening with hydraulic folding conveyors.

Easy to move

Use the same trailers you use to move a mid-size excavator

Video Gallery

RM HS5000M Specs

| Capacity | 300 tph 330 TPH |

| Screen-box | 3,660 x 1,420 mm 5 x 12 ft |

| Screen-decks | 2 2 |

| Screen angle | 15° - 20° 15° - 20° |

| Feed unit | 6 m³ 7.8 yd³ |

| Engine | 97 kW 130 HP |

| Drive | Diesel-hydraulic Diesel-hydraulic |

| Stockpile height tail conveyor | 2,580 - 3,735 mm 8´6" - 12`3" |

| Stockpile height mids conveyor | 3,670 mm 12' |

| Stockpile height fines conveyor | 3,870 mm 12´8" |

| Transport dimension | 13,440 x 2,730 x 3,200 mm 44´1" x 9´0" x 10´6" |

| Weight | 24,500 kg 54,013 lbs |

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.