How does an Impact Crusher work?

Ideal for recycling, primary and secondary crushing applications.

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall. The striking and impacting causes the material to shatter into smaller pieces. The result is a very homogenous and cubical product leaving the crusher box.

Good for processing reinforced concrete, asphalt, cinder blocks, sand & gravel, soft rock, and hard rock.

Ideal for producing a spec product without the need of a primary jaw crusher.

Material produced by an impact crusher is easier to grade and compact making it perfect for base and subbase.

There are 2 main types impact crushers - horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers.

The horizontal shaft impactors are the most common impactor type that can be used in recycling, primary and secondary crushing applications. This type impactor will take reasonable size pieces and produce small output material.

Vertical shaft impactors are designed to process already small material even smaller and are therefore used in a tertiary crushing application (e.g. producing manufactured sand).

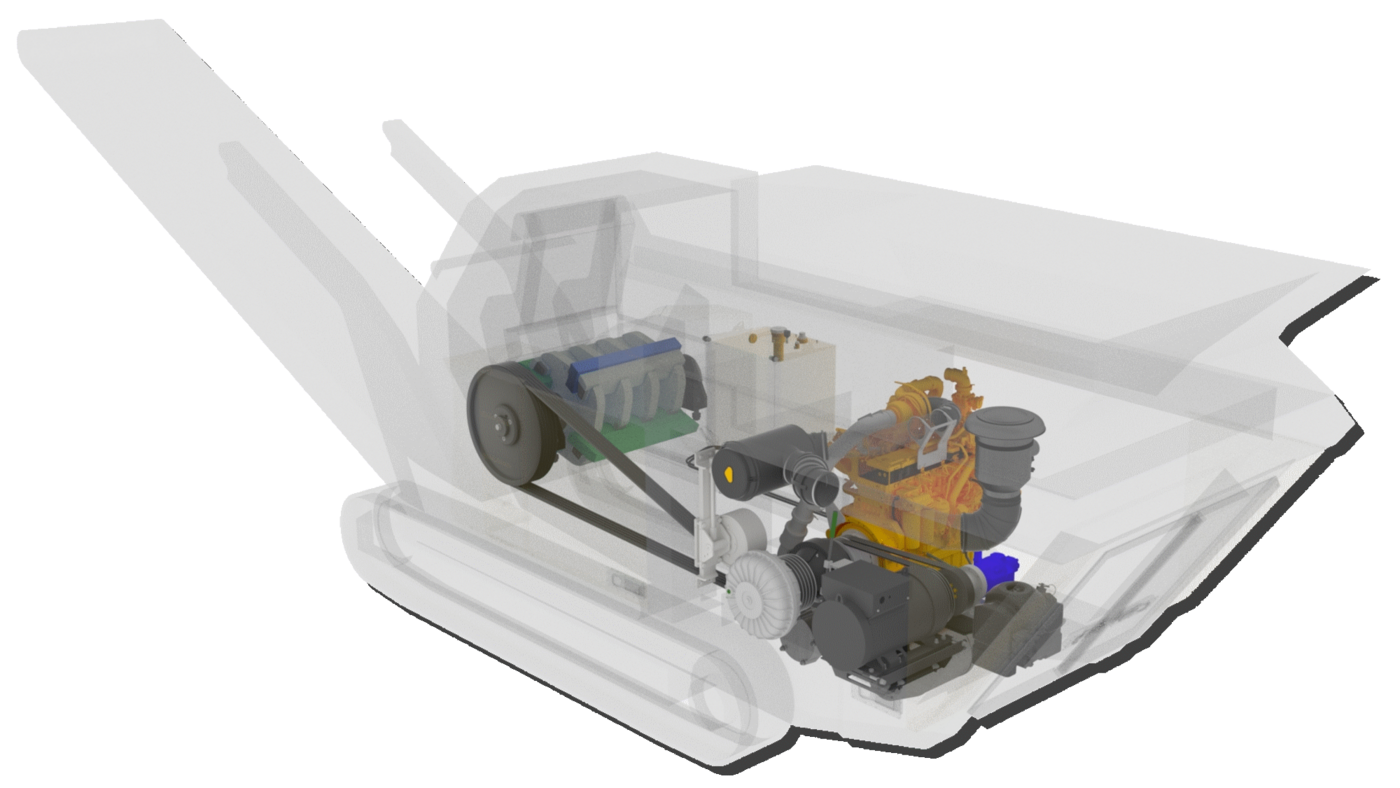

The crusher box includes a rotor with hammers (also called blow bars). Depending on the rotor style you will have either 3 bars or 4 bars. Hammers are cast iron replaceable wear parts that are actually in contact with the material. They are designed to withstand the many impacts of the material. The impact wall (also called apron) has several crushing stages and is armoured by thick wear plates.

Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.

On a mobile unit impact crushers are driven directly by a diesel-engine or indirectly driven by an electric motor or a hydraulic pump.

There are different rotor body styles. Most common are 3-bar and 4-bar rotors. This example is a 4-bar rotor that can be operated in the following two operation modes:

The inlet opening defines the overall feed-size. As a rule of thumb it is recommended that the maximum feed size is 80% of the inlet opening width.

A chain curtain prevents rocks being ricocheting back ensuring operator safety.

The impact wall is typically hinged and can be adjusted hydraulically. The apron is typically armored with replacedable impact plates. Some crusher types need to replace the entire impact wall once it is worn out.

Impact crushers is a versatile crusher that can be used to process natural rock and recycle materials alike. Many people claim that you can't process hard rock with an impact crusher. This is not entirely true because it depends on the breaking characteristics of the rock and the feed size.

Reinforced concrete, demolition material, asphalt millings, washout concrete, high PSI runway concrete, brick & masonry.

Every rock is different even if it is the same type of rock. There is soft limestone and there is hard limestone. Please consult a crushing expert to verify your application.

The beauty of impact crushers is their versatility in terms of input material and output size. There are many different designs out there but generally speaking impact crushers can produce material from 3" down. The smaller the input material the harder it gets to crush. The output gradation can be adjusted through various settings.

The higher the speed the more fines are produced.

Altering the distance between the rotor and the impact wall influences gradation and overall output size.

Common hammer setups are 2 high 2 low or 4 high hammers.

On most crushers this works hydraulically. The aprons need to be adjusted when you want to produce a different output material or when you need to readjust your crusher settings to accomodate the wear progress.

RUBBLE MASTER impact crushers use a simple design to change the crusher setup easily, quickly and safely within minutes. The unique proprietary crushing chamber design allows operators with limited impact crushing experience to operate our machine efficiently from day one.

Wear items are chewed up in the crushing process and need to be monitored and changed frequently. The higher the abrasion, hardness, and fines-content the faster the wear. The rotor body holds hammers in place through a sliding system (see picture) or they are lifted in and wedged in place.