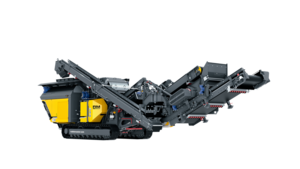

The Evolution of Productivity and Ease of Use

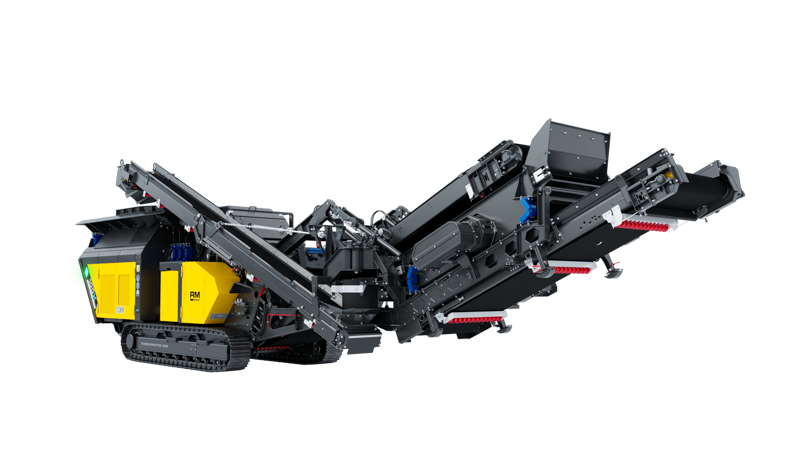

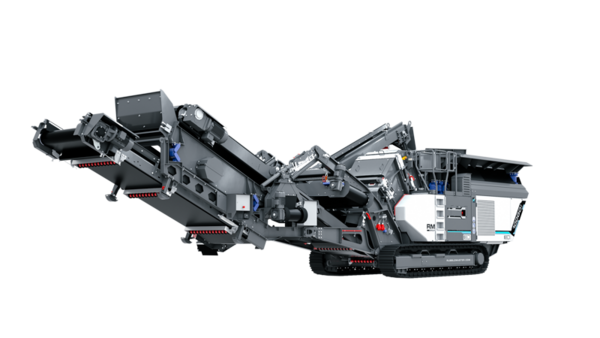

The RM 100X builds on the legacy of the RM 100GO!, evolving into a more powerful, intuitive machine. Despite its compact footprint, it delivers the output of much heavier crushers. A fuel-efficient diesel-electric direct drive cuts operating costs and maintenance, while advanced RM NEXT features such as the new digital display and a new human-machine communication concept take productivity, safety, and ease of use to the next level—so you can get more done, with less hassle, every day.

17% More Inertia

Produce a more consistent end-product and maximize uptime.

New Operating Experience

A new experience operating a compact impact crusher. Common sense solutions make the hardest parts of crushing easy.

Improved Safety

Trust your guys around the machine

Since 1991, One Thing Hasn’t Changed: Everything Keeps Improving.

The RM 100X features RUBBLE MASTER’s proprietary crushing chamber, engineered for maximum performance and efficiency. Its proven geometry and 17% more rotor inertia deliver consistent sizing, greater stability, and higher uptime across all a wide range of materials including concrete, asphalt, C&D waste, and natural rock.

3 Crushing Stages

Single apron design with top and bottom (CSS) adjustment.

4-Bar Rotor

Adjustable rotor speed.

Fast & Simple Hydraulic Adjustments

Only one adjustment necessary.

Built to Keep You Crushing Longer

We understand that if your crusher is down, your crew is down, and you are bleeding money. Our tracked impact crushers assist you in overfeeding situations, so you can resolve issues quickly and keep production high.

Overload Protection

The RM Release System allows uncrushables to pass without interrupting the crushing process. This minimizes the risk of damage while keeping production high.

Jam Detection

Material blockages can result in serious belt damage. RUBBLE MASTER tracked impact crushers shut down the operation automatically to reduce the risk of damages.

Efficient Material Discharge

Smooth and short exit channel, strong conveyor sealing, and heavy-duty belting ensure a smooth material flow.

Adjust Everything with One Operator

The hydraulic folding and swiveling return conveyor makes it easy to switch from an open to a closed-circuit operation in minutes.

Operate with the Touch of a Button

The operation of a RUBBLE MASTER impact crusher is unlike any other crusher. We focus on making machines less complex so that you can start crushing without the lengthy training necessary, because we believe everybody should be able to operate a crusher.

Self-Regulating Feeder

Performance peaks can stall an impact crusher. The self-regulating feeder adjusts the speed so that you process your material smoothly and keep crushing.

Track & Crush Simultaneously

Without track & crush, you are forced to move the finished product with a conveyor belt or wheel loader. Moving the crusher allows you to windrow the material and keeps you crushing.

RM Release System

Oversized slabs may ride on top of hammers without getting crushed. You can resolve the blockage and keep crushing with the touch of a button.

RM XSMART Telemetry Provides More Intelligence About Your Operation

Access machine telemetry and track tonnages conveniently on your cell phone or computer (optional belt scales).

12" Ultra-Bright Display

Enjoy crystal-clear visibility and intuitive control in any lighting condition. Access more digital assistance and diagnostic tools right at your fingertips, so you stay informed, troubleshoot faster, and maximize uptime.

Real-Time Insights

Monitor machine stats and troubleshoot issues faster.

Advanced Operator Guidance

The setup advisor helps operators get an initial recommended configuration for a specific application without flicking through the manual.

Produce a Cleaner End-Product. Automatically.

The optional wind sifter uses an adjustable air stream to segregate lightweight debris, such as roots and fabrics. Without the wind sifter, you must manually pick contaminants and interrupt your operation more often to clean your screen deck. Improve your bottom line with aggregates people wait in line to buy and less labor involved.

Save Up to 30% on Fuel With our Diesel-Electric Direct Drive

compared to traditional diesel-hydraulic compact impact crushers

Fewer Issues Crushing Asphalt

Our efficient drive train requires less cooling. Thus, RUBBLE MASTER utilizes wide-core radiators to minimize dust build-up and premature overheating.

Works Well in Extreme Temperatures

No heating up of hydraulics in winter and no overheating in summer.

Save Up to 70% Hydraulic Fluid Costs

Our small hydraulic system is used for auxiliary functions only. Say goodbye to bursting hoses and leaks.

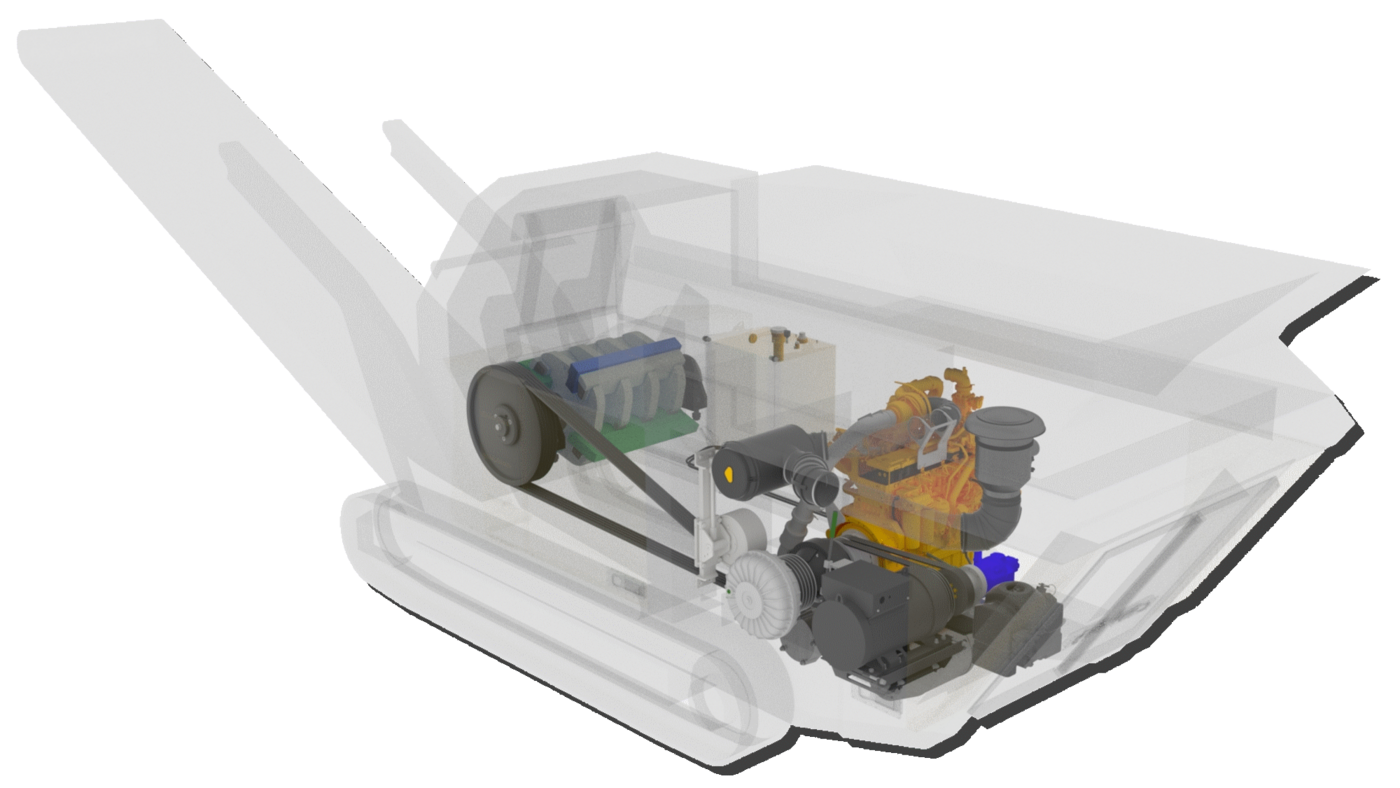

Direct driveX

The diesel engine drives the rotor directly. The RM 100X can be ordered with an optional hybrid drive, in which an electric motor drives the rotor. This option lets you operate the crusher from the grid (50Hz grid power required).

GeneratorX

The generator produces the electric power to run conveyor belts, feeder, and shaker motors.

Small hydraulic pumpX

The small hydraulic system is needed to operate auxiliary functions such as cylinders to setup the machine and adjust the crusher geometry as well as tracking the machine.

Clutch assemblyX

The rotor is engaged/disengaged through a manual clutch. A hydraulic coupling ensures a soft start of the rotor.

Simple Maintenance.

Maximum Uptime.

At RUBBLE MASTER, we understand you want to feed the crusher. If you waste time with lengthy processes, you lose production and profits. That’s why we make the machine setup, daily maintenance, and troubleshooting as easy as possible, so you spend more time crushing and less time running around the machine and figuring out what’s next.

Ground Based Service

Generous access to crusher and engine. There is no need to climb ladders with heavy items.

Improved Diagnostics

Start/stop functions individually for testing.

Readily Available Schematics

View PDF manuals on the display like on your computer.

Perfect for Any Jobsite

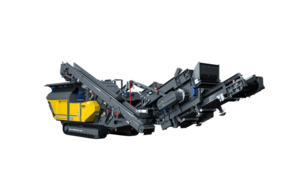

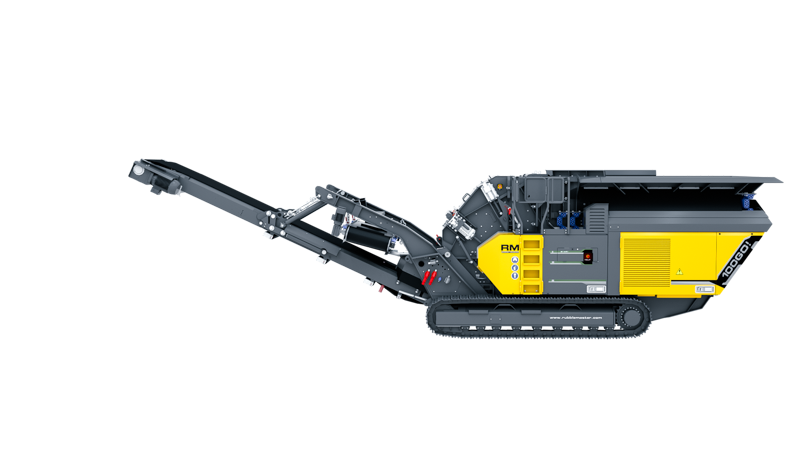

Contractors are facing thinner margins due to an increase in smaller jobsites, neighbors’ complaints, and longer trucking times. One versatile RUBBLE MASTER machine can crush any on-site material volume, from just a few hundred tons to very high volumes, virtually putting money back into your pocket.

Surprisingly Quiet Crushing Operation

Small Footprint

Ideal for on-site crushing where there is little room for setting up large crushing spreads.

Easy to Move

Use the same trailer you use for your excavator.

RM 100X Specs

| Capacity | up to 250 tph up to 275 TPH |

| Inlet opening | 960 x 700 mm 38" x 28" |

| Ideal feed size | 560 mm 22 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 3.3 m³ 4.3 yd³ |

| Feed height | 3,000 mm 9' 10" |

| Prescreen Grizzly (standard) | 1,500 x 900 mm 4'11" x 2'11" |

| Screen-box | 1,300 x 3,000 mm 4 x 10 ft |

| Drive | diesel-electric diesel-electric |

| Transport dimension | 14,700 x 2,860 x 3,160 mm 48'2" x 9'4" x 10'4" |

| Weight (no options) | 31,000 kg 68,350 lbs |

| Weight incl screen attachment | 35,810 kg 78,950 lbs |

Talk to an Expert

Have a question? Fill out the form, and a material processing expert will be in touch with you as soon as possible.

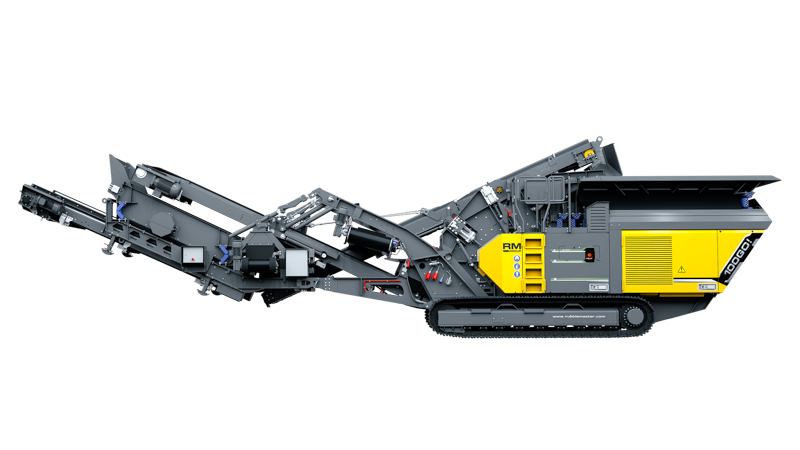

Hybrid Crusher Option

Hybrid Crusher Option

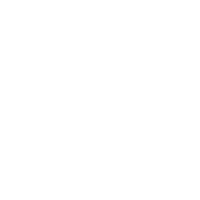

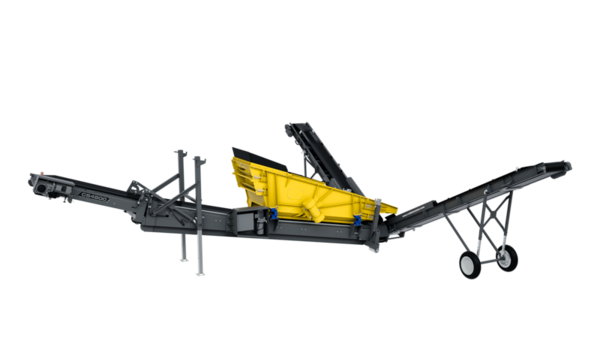

2-Deck Screen Attachment

2-Deck Screen Attachment