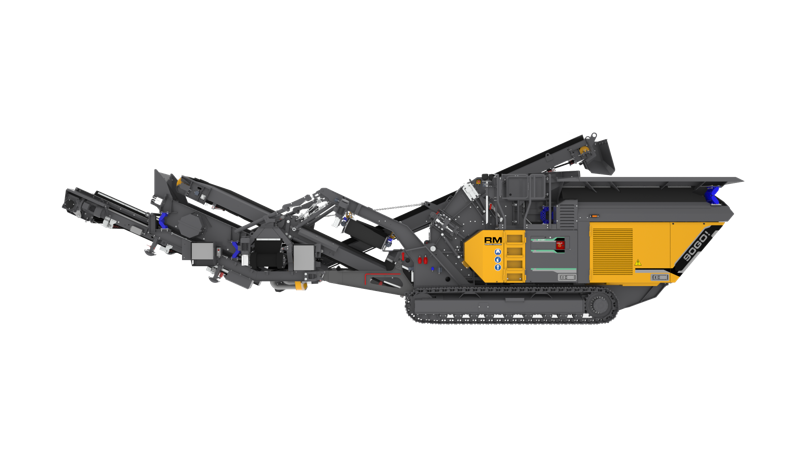

RM 90GO!

Compact Impact Crusher

The Absolute Best Compact Impact Crusher for On-Site Crushing

When crushing on-site you need mobility and performance. The RM 90GO! is the complete package that allows you to tackle small and large crushing jobs so that you can do more job and grow your business faster.

Performance

Some have to choose between performance or mobility. You chose both.

Ease of Use

A new experience operating a compact impact crusher. Common sense solutions make the hardest parts of crushing easy.

Safety

Build from the ground up with operator safety in mind so you can trust your guys around the machine.

Your Customers will be Impressed,

Your Competitors Jealous.

For more than 30 years, we’ve designed and manufactured our compact impact crushers to deliver best-in-class performance without sacrificing mobility

Spec Material

Ideal for base (e.g. ¾“-) and subbase material (e.g. 3"-) that meet spec. Adjustable gradation and output size. High quality cuboid aggregates.

Closed-Circuit Crusher

The RM 90GO! Compact Impact Crusher features a 4' x 8' on-board screen for closed circuit production of spec material..

Self Regulating Feeder

Performance peaks can stall a compact impact crusher. The self-regulating feeder adjusts the speed, so that you process your material smoothly and keep crushing.

Dominate Concrete Crushing Jobs with Ease

Extra Strong Magnet

Built to liberate and segregate encapsulated rebar effectively to produce a clean end-product.

Smooth Material Flow

Optimized feeder design to reduce the risk of overfeeding and blockages. Integrated pre-screen to bypass fines to reduce wear.

Heavy-Duty Belting as Standard

Smooth "aggregate" conveyor belts struggle to withstand rough applications. That's why we use a multi-ply chevron RIP-STOP belt so that you can keep crushing when the belt gets punctured.

The RM Release System Keeps You Crushing Longer

Materials don't come in convenient sizes or shapes. In case the material doesn't fall into the action radius of the impactor you can open the apron via the radio remote control so the material gets caught by the rotor and you keep crushing.

Operate with the Touch of a Button

The operation of a RUBBLE MASTER compact impact crusher is unlike any other crusher. We focus on making machines less complex so that you can start crushing without the lengthy training necessary because we believe everybody should be able to operate a crusher.

Simple & Intuitive

We’ve taken the complexity out of mobile crushers. Because “safety and ease of use” is our top priority!

Radio Remote Operated

Run the crusher conveniently & safely from the cab.

One-Man-Operation

No need for a large crew or specilized knowledge.

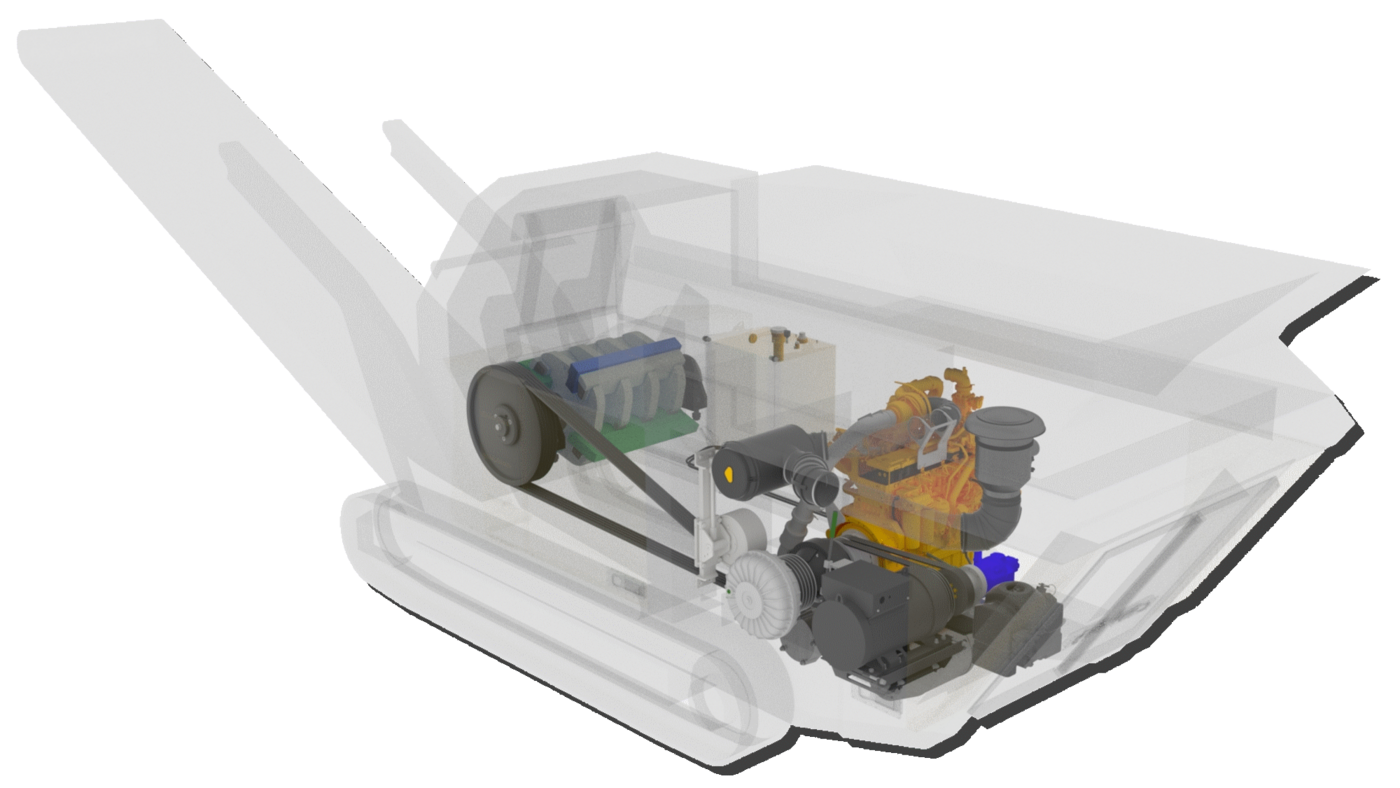

Save Up to 30% in Fuel With our Diesel-Electric Direct Drive

compared to traditional diesel-hydraulic compact impact crushers

Since 1991 We are the Experts in Electric Crusher Drives

We utilize the most reliable electric motors and feature refined controls.

Works Well in Extreme Temperatures

No heating up of hydraulics in winter and no overheating in summer.

Save big on hydraulic fluids

Our small hydraulic system (30 gal) is used for auxiliary functions only. Say goodbye to bursting hoses, leaks, and DEP citations.

Direct-driveX

When the manual twin-disc clutch is engaged the rotor is directly driven by the diesel-engine.

GeneratorX

The generator produces the power for running the shaker motors of the feeder and screen attachment as well as the motors for the conveyors.

Small hydraulic pumpX

The crusher doesn't need the hydraulics while in operation. The relatively small hydraulic system is used to operate cylinders during the machine setup and daily maintenance, and for tracking the machine.

Clutch assemblyX

The clutch assembly consists of a manual twin-disc clutch and a hydraulic coupling for a soft start.

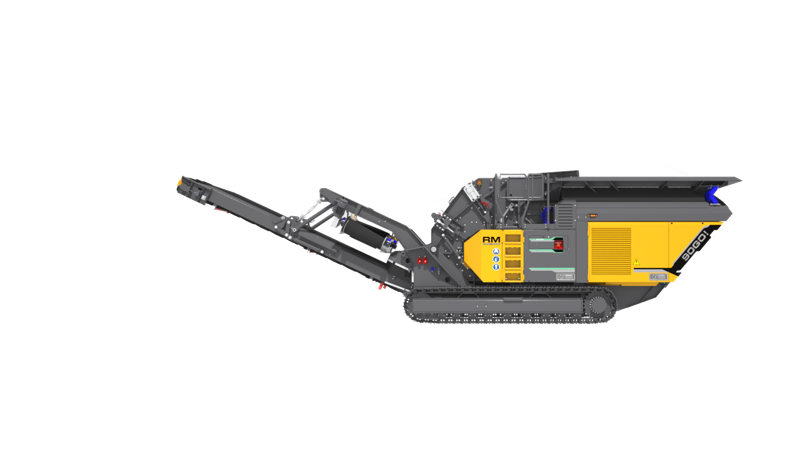

Move Anytime, Anywhere

Say goodbye to burdensome permitting, escorts, and long setups. You’ll be finished with the job before your morning coffee cools.

Precision Movements

The refined controls allow for exact maneouvers on the job and while loading.

Fits on Most Trailers

Use the same trailer you use for your excavator.

15 Minutes From Trailer to Crushing

A single operator can get the crusher ready without the need of special hand tools.

Perfect for Any Jobsite

Contractors are facing thinner margins due to an increase in smaller jobsites, neighbors’ complaints, and longer trucking times. One versatile RUBBLE MASTER machine can crush any on-site material volume, from just a few hundred tons to very high volumes, virtually putting money back into your pocket.

Bar None - The Quietest Crusher

Suprisingly quiet crushing operation.

Small Footprint

Ideal for on-site crushing where there is little room for setting up large crushing spreads.

Track & Crush Simultaneously

Eliminates the need for an additional wheel loader or stacking conveyor on-site.

Video Gallery

RM 90GO! Specs

| Capacity | 200 tph 220 TPH |

| Inlet opening | 860 x 650 mm 34" x 25" |

| Ideal feed size | 500 mm 20 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 2.6 m³ 3.4 yd³ |

| Prescreen Grizzly (standard) | 1,050 x 800 41" x 31½" |

| Engine | 194 kW 260 HP |

| Drive | diesel-electric diesel-electric |

| Screen-box | 1,100 x 2,300 mm 4 x 8 ft |

| Transport dimension | 13,470 x 2,550 x 3,050 mm 44'2" x 8'5" x 10' |

| Weight | 28,400 kg 62,500 lbs |

RM XSMART Telemetry

RM XSMART Telemetry

|

Operating a RUBBLE MASTER

is just…awesome.

Don’t just take our word for it.

"What's unique about Gerald Hanisch [owner of RM Group] and RUBBLE MASTER is that they are always listening and looking for any possible improvements for the equipment."

Dave Schielein, Ironhustler Excavating

Purchase Your Crusher the Easy Way

RUBBLE MASTER Finance provides leasing and financing solutions to keep your business productive, efficient, and competitive within the industry by offering a suite of financing products that can be customized to meet the most complex budgetary needs

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.