A Quick Guide to Choosing the Right Mobile Screening Plant for Your Business

An undersized or wrong mobile screening plant costs money. Here are some considerations to maximize profits.

Mobile Screening Plants are used for screening natural rock, topsoil, asphalt millings, organics, and many other materials. Screening is the process of segregating the material by size to produce a homogenous end-product.

Mobile Screeners can be used stand-alone to screen topsoil or gravel or integrated with aggregate systems to produce finished aggregates for concrete and asphalt products.

Choosing the right screener depends on your materials and production goals.

Mobile screening plants come with various-size screens and are built on a chassis with tracks so you can move easily on the job and mobilize the plant in between job sites. Each type of screening plant has its uses and strength. Here is a quick overview:

are highly versatile screening plants suitable for virtually any screening application. Therefore, this type of screener is popular among contractors who have little control over their feed and need the freedom to use it in many applications.

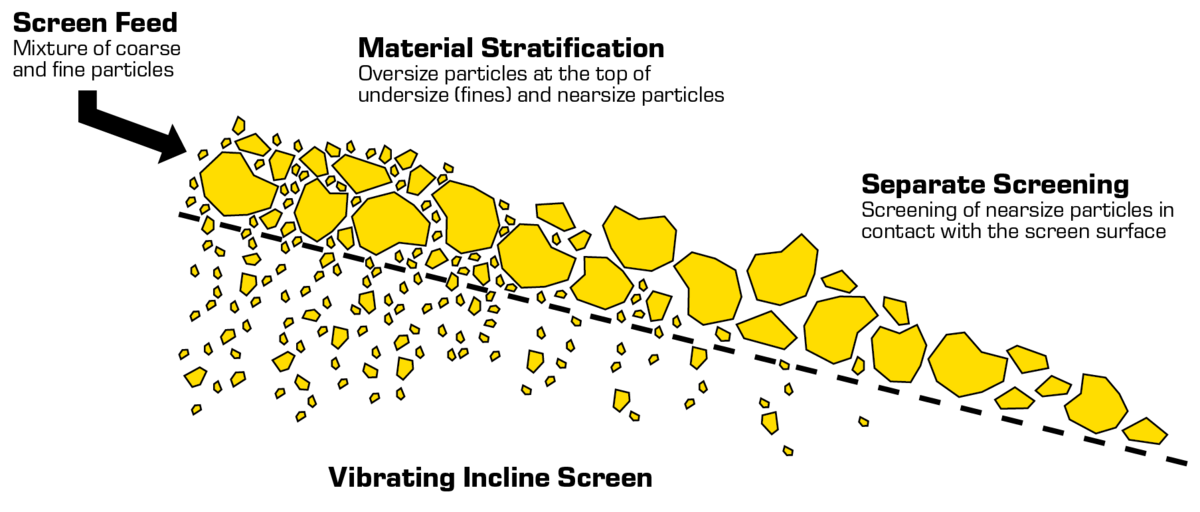

Incline Screens are high-performance aggregate screens. Commonly found in quarries, gravel pits, and sand pits to produce finished aggregate products. They can be easily integrated into aggregate systems or fed stand-alone with large wheel loaders.

Scalping and incline screens are the most sold type of tracked screener and work well in the same applications. However, there are many differences between them. Learn more about the differences in this blog article.

Horizontal screens are an out layer in the mobile screening plant categories. This type of screener is commonly used in aggregate systems and provides more precision than an incline screen. It works without the aid of gravity to move material down the screen and relies solely on the screening plant’s stroke to pitch the material over the screen deck.

Contrary to the previous screener types, the trommel screen does not feature a vibratory screen deck but a rotating trommel that turns the material to screen the product. Most mobile trommel screens are suited for topsoil screening, organics, and other lightweight materials. Less commonly seen are heavy-duty trommel screens for screening large rock boulders in heavy-duty quarrying applications.

When selecting a mobile screening plant, you want to look at your feed material and the average feed size. It is important to consider other applications besides your primary application.

If you feed large chunks of material, a scalping screen is your tool of choice because incline screens, trommel screens, and horizontal screens can’t take large chunks.

If you feed mostly small materials such as sand & small gravel or crushed aggregates, an incline screen provides more capacity and faster screening than a scalping screen or a trommel.

Trommel screens are mostly used in lightweight organic screening processes such as compost, topsoil, and mulch rather than rock screening processes because large chunks would bounce violently in the rotating drum causing premature wear and damage.

Screen decks needed affect the selection of the mobile screening plants or require the combination of multiple mobile screening plants to achieve a desired production goal.

| Scalping Screens | Incline Screens | Horizontal Screens | Trommel Screens |

| always feature 2 screen decks. Some offer a single deck (2-way split) option | are available with 2 or 3 screen decks | are available with up to 3 screen decks | feature mostly a single-screen deck |

Your daily output requirement determines the size (class) of your desired mobile screening plant. The available screen area is a strong indicator of production capacity.

Most mobile screener nomenclature references screen width and length of the available screen area.

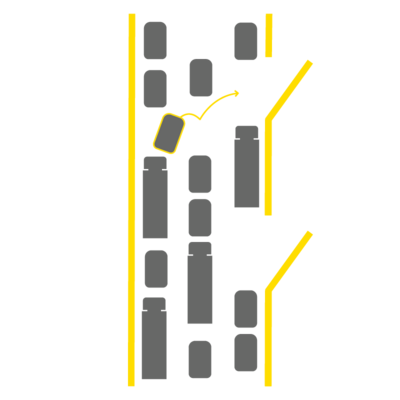

More screen width spreads out material and means more capacity. Similar to a highway that has more lanes to suit more traffic.

A longer screen deck gives the material more time to find an opening and thus adds precision and less carry-over. This is similar to having more time to change lanes and find an exit on a highway.

While screen size is the main performance indicator, there are more parameters it is worthwhile looking at:

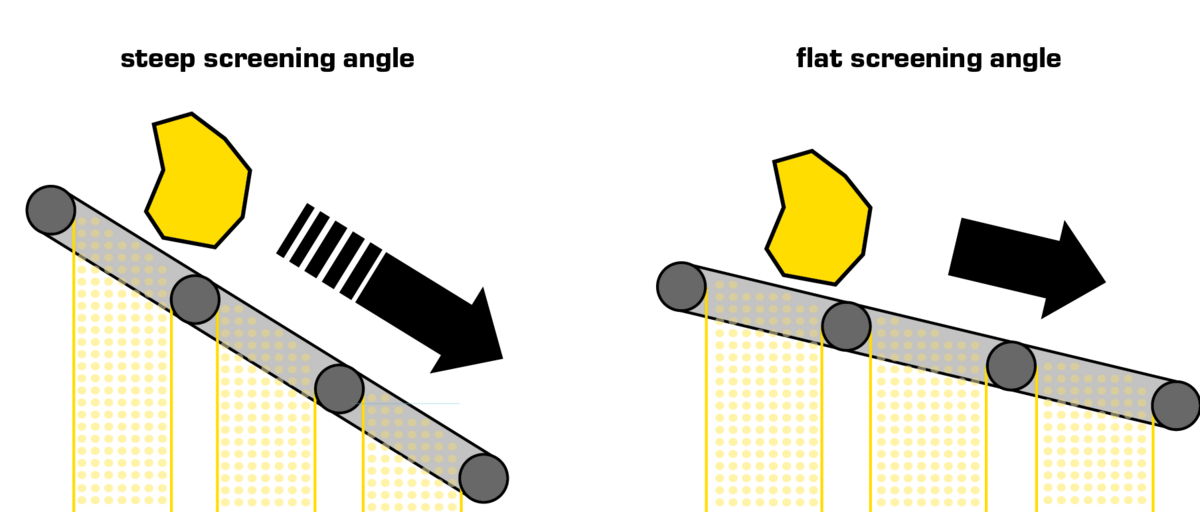

Screen angle

Most vibratory mobile screening plants feature an adjustable screen angle. Steeper screening angles accelerate materials and translate into more capacity. Flatter screening angles decelerate material for more efficiency and precise screening.

Incline screens feature a steeper angle for fast screening after a crushing spread. A horizontal screen features no incline for maximum precision.

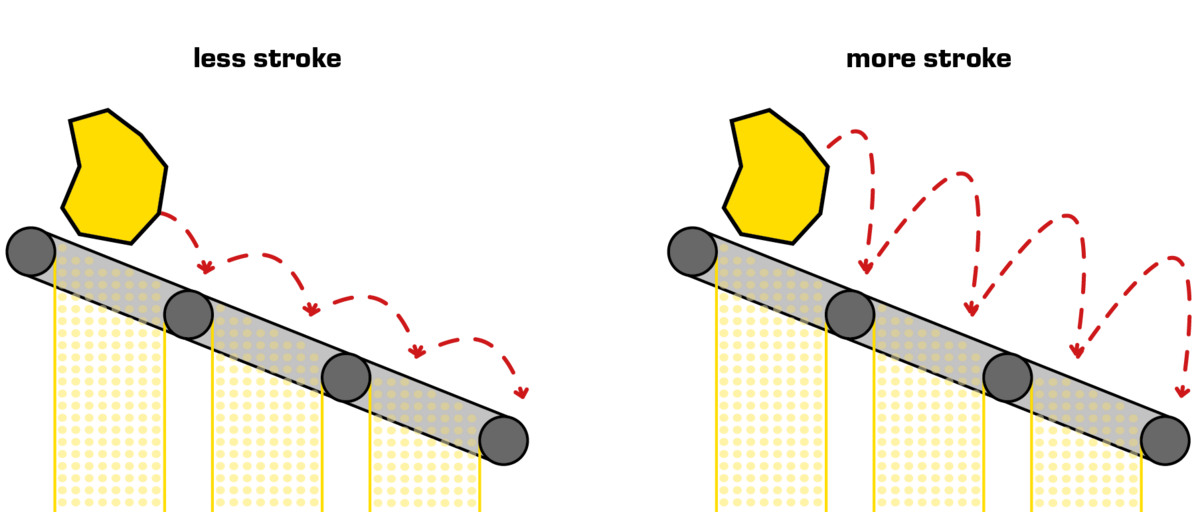

Stroke (or throw) is the distance a screen moves vertically. This parameter is influenced by the unbalanced weights on the screen shaft. If a stroke is too long, the material will travel too far and miss much of the open screen area. If the stroke is too short, the material stays in place, and you risk plugging the screen openings.

More stroke is used for coarser openings, while less stroke is used for finer openings.

Screen RPM (speed)

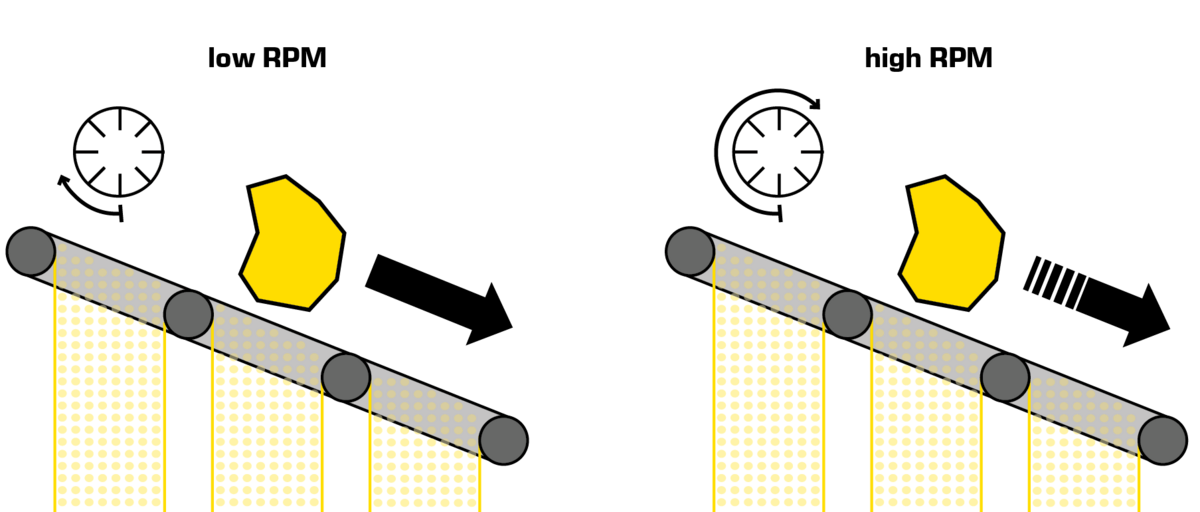

Speed is an important parameter as, together with stroke, it creates material acceleration. The screen RPM (rotations per minute) can be changed by adjusting the hydraulic motor’s flow valves that drive your screen box.

A higher RPM accelerates the material (carrying capacity), while less RPM decelerates the material and increases efficiency.