Crushing Gravel

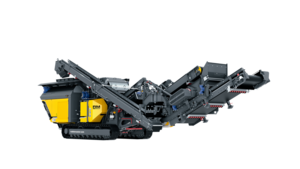

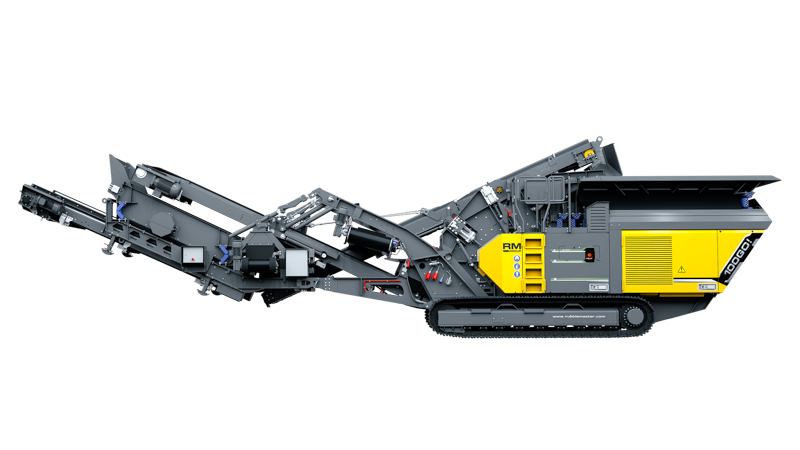

RUBBLE MASTER offers a range of mobile impact crusher that work billiantly for processing sand & gravel. On-board screening options help to achive high outputs with minimum wear.

Crushing Gravel

RUBBLE MASTER offers a range of mobile impact crusher that work billiantly for processing sand & gravel. On-board screening options help to achive high outputs with minimum wear.

What is a gravel crusher?

A mobile crushing plants reduces gravel in size. Dependnig on your gravel crushing application (material characteristics, input size, desired output size) you can use impact crusher or compression crushers such as jaw and cone crushers. Before and after the crushing process screens may sift throught the material and store it in different stockpiles accoring to their size.

Input material

The material type and its characteristics such as hardness, input size and abrasiveness define the type of crusher and material pre-processing requirements.

Output material

The finished material sizes and quality requirements define the type of crusher and further processing requirements. This could result in an additional crushing or screening stage.

Material volume

The amount of material you need to process defines the size of the crusher or machine class.

Impact Crushers Are Gravel Crushers

RUBBLE MASTER offer a large range of mobile impact crushers to process natural rock and recycling materials.

High Reduction Ratio

High performance even with small infeed material.

Quality Products

Perfectly cubical end product that meets spec. Impact crushers are better suited for fractionating round river rock.

More Materials. More Specs.

Produce a great variety of finished products from crusher run gravel to clear stone products.

Improve your Bottom Line

without Changing your Process

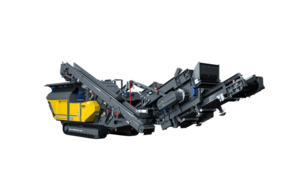

Crushing gravel with a lot of fines can result in accelerated wear. The patented RM Active-Grid is a high-performance pre-screening option to increase production up to 30% so that you can produce more product in a day and grow your business.

A Small Investment with a Huge Return.

Less dowtime. More thourghput. More Money.

Talk to an Expert About Pre-Screening Options

Contact our material processing specialist to evaluate the best pre-screening option for your material processing operation.

What is Crusher Run Gravel?

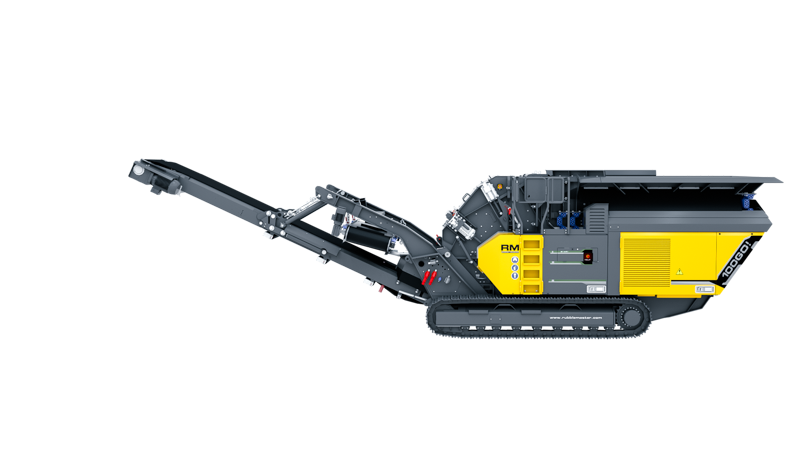

Crusher run (also referred to as crush and run) describes material that passed through the crusher once to do an initial reduction in size. The material is comprised of crushed stone and fines. Crusher run gravel is typically used for driveways and ub-bases, or it is refined further with a screening plant to produce base (surface) materials or clear stone products. RUBLE MASTER's line of mobile impact crushers produce crusher run material up to 3"-. The top size varies greatly if not controlled by a screening plant.

Open Circuit Production

Crushing 16" river gravel with a RM 70GO! Compact Crusher to produce a 2"- crusher run gravel product.

How to seperate gravel and sand?

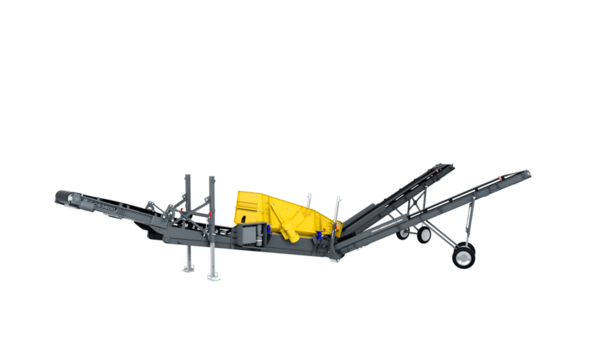

RUBBLE MASTER offers a range of screening machines to produce spec material such as fines, stone dust, chips, rip-rap, pea gravel, and other clear stone products.

Application Videos

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely contractors and aggregate producers world-wide.

Crusher screen attachments

Crusher screen attachments