Stationary vs Mobile Stone Crushers: Choosing the Right Stone Crushing Machine

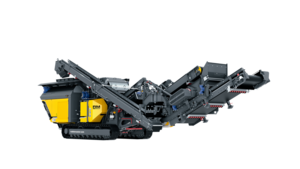

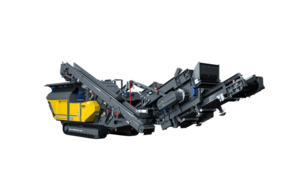

Choosing between stationary and mobile stone crushing machines is crucial for optimizing efficiency, costs, and flexibility in aggregate production. Mobile plants offer on-site adaptability, reduced hauling, and lower labor costs, while stationary plants deliver high capacity and long-term stability. Understanding the advantages and limitations of each option helps operators make informed decisions for quarrying, recycling, and construction projects.