Why Contractors Get Into Mobile Rock Crushing

Across Europe and the United States, contractors typically enter crushing for three reasons:

✅ Cost Control

Hauling and dumping material gets more expensive every year. Mobile rock crushing eliminates:

- Disposal fees

- Long haul distances

- Waiting on third-party crushers

✅ Schedule Control

Owning your own crusher means:

- No waiting for subcontractors

- Crushing when you are ready

- Finishing jobs faster

✅ New Revenue Streams

Crushed material can be:

- Reused on site

- Sold as aggregates

- Used to bid more competitively on future projects

Mobile rock crushing turns waste and natural rock into usable material—and profit.

The Big Misconception: “I Just Need a Crusher”

This is where many newcomers underestimate the challenge. A mobile rock crushing business is more than a single machine. You need to think in terms of a system.

What You Actually Need to Start Mobile Rock Crushing

1. The Right Crusher (Not the Biggest One)

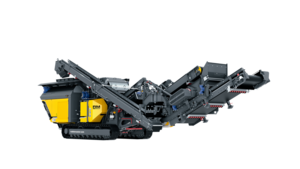

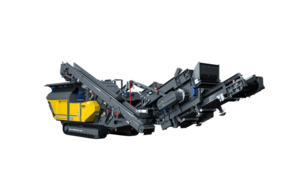

For newcomers, compact mobile crushers are often the smartest entry point.

Why?

- Lower investment risk

- Easier to transport and operate

- Faster to deploy on changing job sites

- One or two operators instead of a full crew

This is exactly why RUBBLE MASTER created the compact crusher category—to allow contractors to start crushing without building a quarry-level operation.

💡 Bigger machines only make sense once crushing becomes your primary business.

2. Support Equipment (You May Already Own It)

Many contractors already have most of what they need:

- Excavator or loader to feed the crusher

- Dumpers or trucks for material movement

- Water source for dust suppression

- Support equipment such as hydraulic hammers and breakers

For mobile rock crushing newcomers, this reduces startup complexity dramatically.

3. Operators & Know-How

Crushing is not “set it and forget it,” but it doesn’t require decades of quarry experience either. It takes more to be a crusher operator. You can’t feed a crusher like you load a dump truck. You have to understand how to feed the machine to maximize production and minimize wear and damage. You have to know how to make the adjustments and keep up with the daily maintenance, recognize unusual wear patterns and react to changing materials and environments.

Modern mobile crushers—especially compact impact crushers—are designed for:

- Simple controls

- Automated overload protection

- Fast setup and teardown

This allows contractors to:

- Train existing operators

- Avoid hiring specialized crusher crews

- Keep operations flexible

RUBBLE MASTER provides operator training at the factory to help you be at your best and get the most out of your machine and maximize your crushing profits.

4. Maintenance & Mindset

Every crusher will break—it’s the nature of crushing rock.

Successful newcomers:

- Perform daily inspections

- Replace wear parts before failure

- Treat crushing like a production line, not a side hobby

Compact crushers are designed to keep maintenance approachable, especially for contractors used to heavy equipment.

5. Regulations & Site Requirements

Depending on location (country, state, municipality), you may need:

- Noise compliance

- Dust control

- Recycling permits

- Environmental documentation

Mobile rock crushing simplifies this compared to fixed plants:

- Temporary setup

- Lower footprint

- Easier permitting in many regions

Starting Small Is a Strategy, Not a Limitation

One of the most common mistakes new crushing entrants make is starting too big.

The most successful contractors often:

- Start crushing their own material

- Learn production rates and costs

- Expand later with screens, stackers, or secondary crushers

Compact mobile crushers make this possible—and profitable—without committing millions upfront.

Why RUBBLE MASTER Is Often the First Crusher Contractors Buy

RUBBLE MASTER didn’t just build a crusher—they created the compact crusher category.

For contractors new to mobile rock crushing, that matters.

What Sets RUBBLE MASTER Apart for Newcomers:

- Designed for mobility and jobsite flexibility

- Compact without sacrificing performance

- Strong focus on safety and ease of use

- Support network helping contractors succeed, not just buy machines

Is Starting a Rock Crushing Business Right for You?

Starting a mobile rock crushing business can be the right move if you regularly handle concrete, asphalt, or natural rock, face rising disposal and hauling costs, and want greater control over schedules and jobsite margins—provided you’re willing to treat crushing as a disciplined, repeatable process rather than a quick fix. On the other hand, it may not be the best fit if crushing needs are rare or unpredictable, you lack trained operators or time for maintenance, or you prefer the simplicity of fixed‑price outsourcing. The bottom line is this: entering mobile rock crushing doesn’t mean becoming a quarry operator, but it does require the right equipment, mindset, and expectations. For many contractors, compact mobile crushing is the practical bridge between outsourcing and full‑scale aggregate production—and that is exactly the space RUBBLE MASTER was built to serve.