Crushers and Shredders Reduce Material in Size. But They Are Not Equal!

Contractors and recyclers often weigh a concrete crusher against a concrete shredder when setting up a concrete recycling workflow. While both machines reduce volume, their outcomes differ dramatically: crushers produce defined, high‑quality aggregates suitable for resale or reuse; shredders mainly tear and reduce material into irregular fractions. The right choice impacts material quality, compliance, throughput, maintenance, and long‑term ROI.

👉 Looking specifically to recycle concrete? Explore concrete recycling with RUBBLE MASTER crushers.

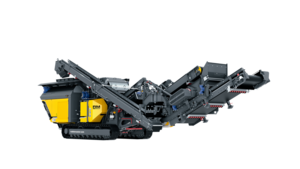

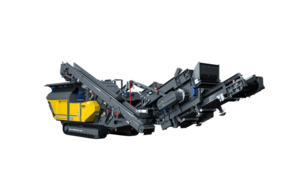

What Is a Concrete Crusher?

A concrete crusher (typically an impact crusher for recycling) is engineered to break down concrete into consistent, defined fractions with cubic shape—ideal for road base, backfill, and high‑quality recycled products. Modern crushers:

- Separate embedded rebar efficiently.

- Deliver multiple fractions with integrated screening options.

- Achieve high throughput to process large volumes quickly.

- Allow fast material switching without heavy component changes.

This makes a concrete crusher the preferred choice for professional concrete recycling and markets where material quality and compliance are non‑negotiable.

What Is a Concrete Shredder?

A concrete shredder is a slow‑speed, high‑torque machine that tears material to reduce volume. Shredders are valued for:

- Robustness against contaminants (e.g., metals and mixed waste).

- High flexibility with diverse feedstocks (wood, green waste, municipal/bulky waste, even car parts).

- Compact transport and lower acquisition cost.

- Lower dust generation than impact crushers and lower energy consumption in some setups.

However, shredders typically deliver one coarse fraction (often 0–200 mm), produce irregular, inhomogeneous particles, and frequently require additional screening—limiting their use when a defined, saleable aggregate is required.

Concrete Crusher vs Concrete Shredder: Side‑by‑Side Comparison

| Criteria | Concrete Crusher (Impact Crusher) | Concrete Shredder (Slow-Speed, Two-Shaft) |

|---|---|---|

| Primary Outcome | Commodity-grade, defined fractions; cubic shape | Volume reduction; irregular, coarse fraction |

| Material Quality | High-quality recycled aggregates suitable for reuse/sale | Lower material quality; often requires additional screening |

| Throughput & Efficiency | High throughput; integrated screening delivers multiple final products | Good production relative to size, but typically single fraction |

| Regulatory Fit | Favored in markets with strict material standards (e.g., quality regulations) | Less desirable where defined fractions & quality compliance are required |

| Contaminants & Mixed Feed | Handles rebar well; better with cleaner concrete streams | Very robust against contaminants; ideal for mixed material |

| Maintenance | Blow bars are straightforward to maintain/replace | Shafts may need rebuilding after ~100–120 hours; expensive downtime |

| Flexibility | Rapid material changes; less heavy tooling changes | Highly flexible for diverse materials; but shaft changes are heavy operations |

| Dust & Energy | May generate more fines/dust; energy use depends on setup | Typically lower dust; lower energy consumption in many cases |

| Acquisition Cost | Higher investment (premium impact crusher) | ~One‑third the price of a high‑quality impact crusher |

| Transport & Footprint | Larger and heavier | More compact and easier to transport |

| Best Use Case | Professional concrete recycling, large volumes, and high-quality end products | Small volumes (<5,000 t/yr), mixed waste processing, volume reduction |

Where Shredders Win—and Where They Don’t

Why shredders are often chosen:

- Competitive pricing and compactness reduce barriers to entry.

- Confidence with contaminants and mixed materials minimizes operational risk.

- Lower dust and often lower energy use align with certain site constraints.

But shredders fall short for concrete recycling when:

- You need defined, cubic aggregates that meet quality standards.

- You require multiple fractions without additional downstream equipment.

- You aim to maximize resale value or reuse in new concrete mixes.

- Maintenance windows and shaft rebuilds (150–200 hours) risk productivity and cost.

- Wear depends on feed size.

Why a Concrete Crusher Is the Best Choice for Concrete Recycling

- Superior Final Product: Crushers deliver cubic, consistent aggregates, ready for road base, backfill, or recycled concrete applications—no guesswork, no excessive fines.

- Integrated Productivity: With built‑in screening, you can produce multiple fractions in a single pass—fewer machines, fewer transfers, faster production.

- High Throughput for Large Volumes: Impact crushers excel at processing big loads fast, keeping projects on schedule and improving cost per ton.

- Compliance & Marketability: In markets with tighter regulations on recycled aggregate quality (e.g., Germany’s stricter material standards), crushers help meet defined fraction and quality requirements, protecting resale opportunities and project approvals.

Operational Practicality: Blow bars are easy to maintain and replace; material switching is quick—no heavy shaft swaps, shaft rebuilds, or prolonged downtime.

When a Shredder Might Make Sense

Choose a shredder if your priority is volume reduction for small annual tonnages (≈≤5,000 tons/year), mixed material streams, and cost containment. It’s also a fit when material quality is not decisive, or when downstream processing is planned (e.g., additional screening or later crushing).

If, however, your outcome requires saleable, defined aggregates and you value fast throughput, less downtime, and compliance, a concrete crusher is the clear choice.

FAQs: Concrete Crusher vs Concrete Shredder

Q1: Can a shredder replace a concrete crusher?

Not for high‑quality recycled aggregates. Shredders focus on volume reduction and typically output one coarse, irregular fraction. Crushers are purpose‑built to produce defined, saleable aggregates.

Q2: What about rebar and contaminants?

Impact crushers are designed to handle rebar in concrete. For mixed waste streams (wood, bulky waste, car parts), shredders are more resilient—but the output isn’t a commodity aggregate.

Q3: Which is cheaper to buy and operate?

Shredders often cost ~one‑third of a high‑quality impact crusher and can have lower energy usage. However, consider maintenance (e.g., shaft rebuilds after ~150–200 hours) and the value of the final product—crushers typically deliver better ROI from saleable aggregates.

Q4: What if my market has strict recycled aggregate standards?

Choose a concrete crusher. Where regulations demand defined fractions and quality (e.g., strict markets like Germany), shredders are less desirable for concrete recycling.

The Bottom Line

If your goal is to recycle concrete efficiently, produce defined, high‑quality aggregates, and meet market or regulatory standards, a concrete crusher (impact crusher) is the best choice. Shredders have a role in small, mixed‑material operations where price and flexibility outweigh material quality—but for professional concrete recycling and strong resale value, go with a crusher.