Impact Crusher Blow Bars

A comprehensive blow bar selection guide to maximize your crushing profits!

A comprehensive blow bar selection guide to maximize your crushing profits!

A comprehensive blow bar selection guide to maximize your crushing profits!

Impact crusher blow bars (also called hammers) are the main wear parts of horizontal shaft impact crushers—and one of the biggest cost factors in crushing operations.

Their job is simple but critical: when material enters the crusher chamber, blow bars strike it and fling it against the impact plates, breaking it down into smaller particles (see also: How does an impact crusher work?).

Over time, the repeated impacts wear the blow bars down, and they need to be replaced. They’re typically made from cast steel with specific metallurgical compositions tailored to different applications. Choosing the right blow bars for your material and operating conditions is key to achieving long wear life and reducing downtime.

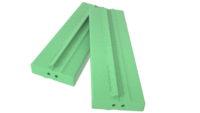

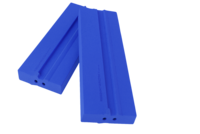

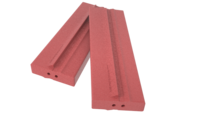

Blow bars are produced in foundries, where they are cast to precise shapes and metallurgical specifications. While the shape can be copied, the metal composition is the real performance secret. Here are the most common types:

Great for breaking tough materials while resisting wear in abrasive conditions. Best for concrete recycling, primary crushing, and applications with larger feed sizes.

These blow bars build on the proven toughness of standard martensitic designs, but with a higher density of ceramic inlays for significantly improved abrasion resistance. The added ceramic content helps extend wear life and reduce changeouts, delivering more uptime in demanding applications.

Excellent wear resistance in abrasive applications such as asphalt recycling or natural stone crushing. They are more brittle than martensitic bars, so they perform best with smaller, controlled feed sizes and minimal uncrushable contaminants (e.g. milling teeth, drilling bits, rebar, tramp iron, aso).

Download our Blow Bar Selection Guide to match your crusher hammers to your feed material, size, and operating conditions.

The wear life of your impact crusher blow bars depends on three main factors: feed material characteristics, crusher settings, and operational practices. Optimizing each of these can dramatically extend blow bar life and reduce downtime.

Feed size has a direct impact on hammer selection and wear rate. Larger feed sizes require higher breaking resistance to withstand the initial impact. Martensitic blow bars with ceramic inlays are a great choice for primary crushing applications and recycled concrete where toughness is essential.

Abrasiveness is determined by the material’s mineral composition. High-silica rock and asphalt are among the most abrasive materials and can accelerate wear if not matched with the right blow bar type.

Fines act like sandpaper inside an impact crusher. Excessive fines quickly wear down blow bars, so pre-screening is recommended whenever possible.

Moisture can also increase wear. When using water for dust suppression, apply only as much as necessary—enough to control dust but not so much that it accelerates wear.

Crusher geometry and CSS (closed side setting) influence how the material is struck and broken. Incorrect settings can cause uneven wear or premature blow bar failure. On two-apron impact crushers, both settings must be correct. RUBBLE MASTER impact crushers feature a single-apron design with three crushing stages, making setting adjustments simpler and more consistent.

Rotor speed controls the number and force of impacts. Higher rotor speeds increase fines production but also increase wear, while lower speeds reduce wear but may lead to more oversize material.

| Rotor Speed | Wear | Fines | Oversize Material |

|---|---|---|---|

| Low | Less | Less | More |

| High | More | More | Less |

The way you run your impact crusher plays a huge role in blow bar longevity.

Fines management is critical. Excess fines inside the crusher create a sandblasting effect on blow bars and other wear parts. Keep your pre-screen grizzly open and consider using a mobile scalping screen to remove fines before crushing, especially with sand & gravel, asphalt millings, or excavated dirt-heavy material.

Rock-on-rock crushing can significantly extend wear life. This requires a steady, even material flow to keep the crusher chamber full. Preparing your material beforehand allows you to maintain a consistent feed. Building a level pad under the feeder helps avoid uneven wear on one side of the blow bars.

Material preparation is essential for avoiding breakage. Tramp iron, rebar, and other uncrushables can damage blow bars instantly. Sorting material with an excavator before feeding ensures these hazards are removed before they enter the crusher.

Changing blow bars on a RUBBLE MASTER impact crusher can be done in 6 easy steps.