Crushing in the rain - blessing or pain?

What’s the best way to crush when the material is wet and has mud?

Some say you are better off crushing beer cans than rock when it is raining, and your material is full of mud. If you are not prepared for it, you struggle to keep crushing and are forced to leave the convenience of your cab and get out in the rain.

Watering down material turns your feed into slurry mud. As a result, your feeder doesn’t convey material forward, your screens start blending over, and you lose production.

Avoid piss-poor planning so that you don’t have to leave your cab that often. The following measures can help you to keep crushing in the rain:

Removing fines (1½“-) before it enters the crusher helps to improve material flow in your feed hopper and reduces material blinding on your screens. The scalper’s belt feeder conveys material reliably onto the screen deck. The screener removes the fines and clay and feeds clean crushable material into your crushing plant. This eliminates the slurry soup in your crusher’s feeder and keeps your screen open longer.

In case you have no room or no budget for a scalping screen a skeleton bucket helps to shake out the mud before feeding it into the crusher.

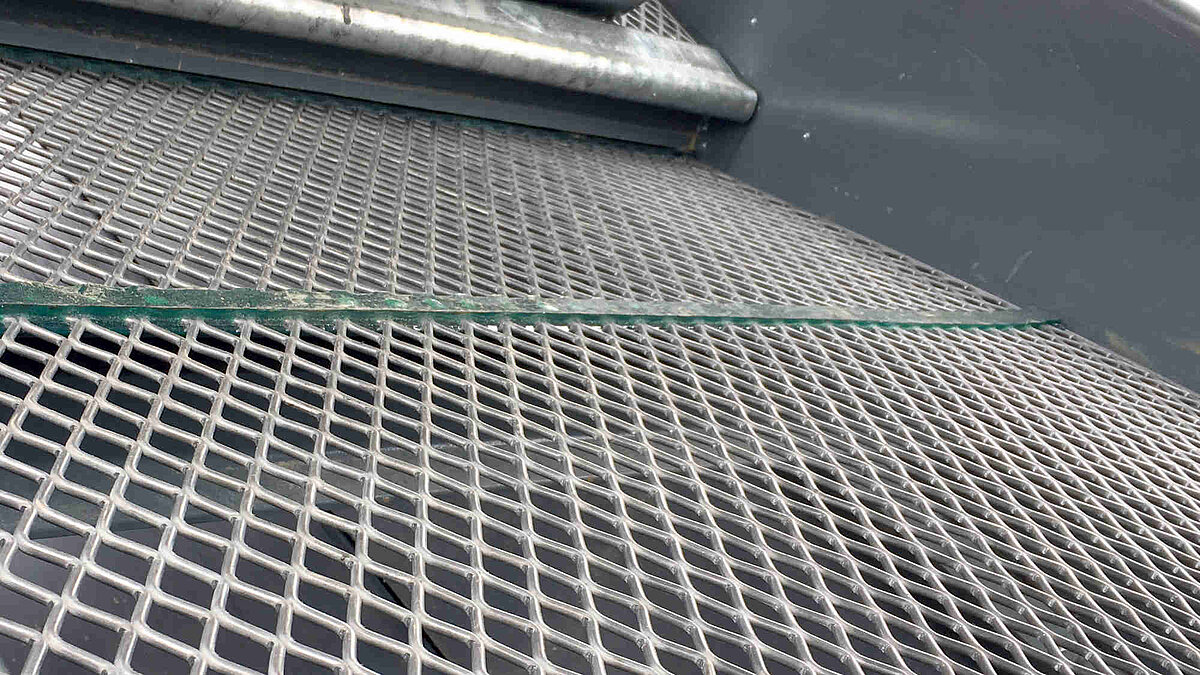

Square mesh screens plug up fast with wet material. Stainless Z slot self-oscillating screens (such as a Flexmat screen) reduce the blinding of your screen. If you can’t keep your screen open, you get more carry over, build up material in your closed loop, and lose production.

Blending dirty & wet material with clean and dry material helps to clear out the crusher. The dry material acts almost like a brush. You might want to save the clean material and use it when the material starts building up so that you can use it to rattle across the feeder and screen when you need it.

Severe blinding problems can be solved with a chain on a rope. It acts like a hammer on your screen media when you clean your screen manually. It probably will increase the wear of your screen media. Some operators are using a bucket tooth on a rope to bounce around in the screen box.

A proper ball deck would be another and more professional alternative to deal with moisture in your feed.

If you can’t keep crushing, you can’t make money. So why are you doing it? Spread out the material and let the sun dry it.