Crush Different To Dominate Serious Projects

Efficiency and the lowest cost per ton are the aims of the game. RUBBLE MASTER understands that when your machine is down, your crew is down, and you are bleeding money. That’s why we provide operators with more feedback to improve their crushing, foresee issues sooner, minimize downtime, and put more product on the ground.

More Performance-Enhancing Options

for a smooth material flow and improved operating costs.

New Operating Experience

Refined controls via a touchscreen control panel. Modern human-machine interface for more clarity about the machine's condition. Troubleshoot issues faster and with confidence to minimize downtime.

Improved Safety

Keeping people from entering the danger zone and climbing the machine. New status lighting for more clarity.

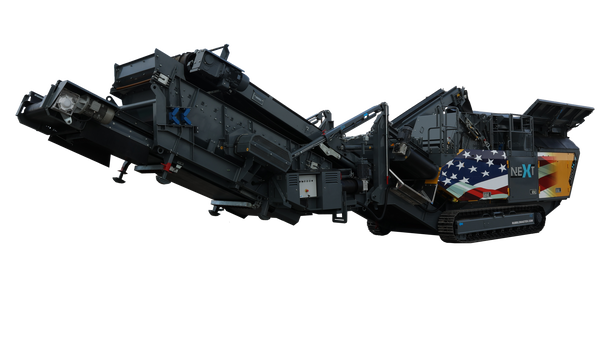

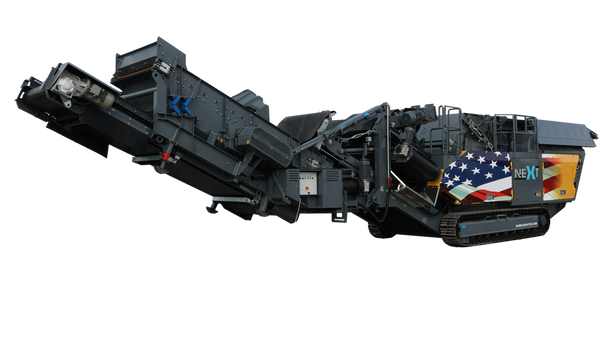

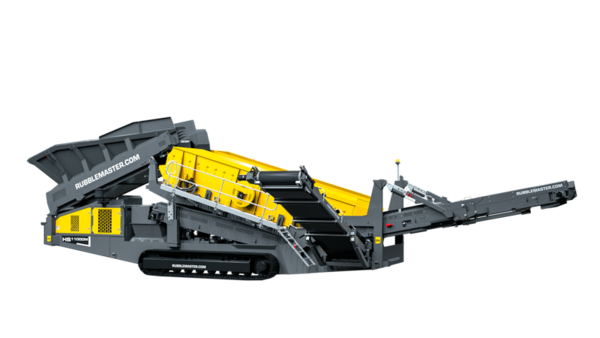

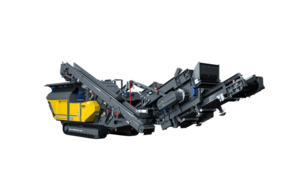

Our Biggest Mobile Impactor

Designed For Those Who Must Keep Crushing

The RM 120X mobile impact crusher delivers a high reduction ratio while being easy to maintain. The 4-bar rotor is driven directly through a 400 HP John Deere diesel engine and can be used in primary and secondary crushing applications. Best of all, it comes with a 5-year / 5,000-hour limited warranty on all main structural components.

Fast Crusher Adjustment

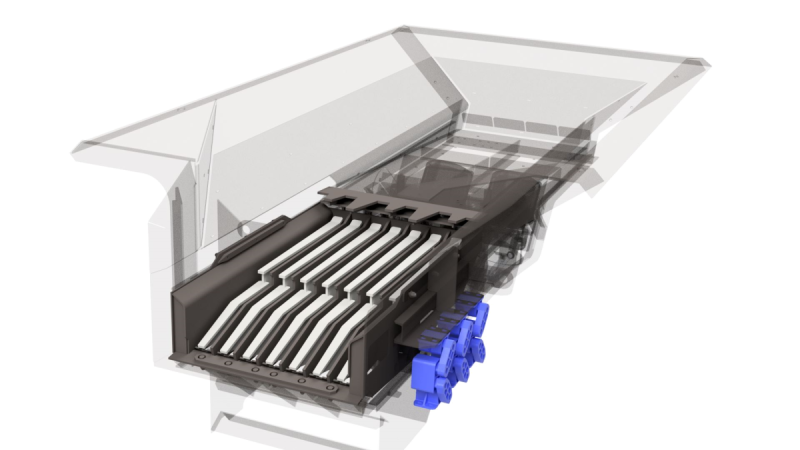

Our proven single impact wall has three crushing stages, allowing for fast and simple crusher adjustment with only one setting.

High Reduction Ratio

Adjustable rotor speeds, baffled impact plates, and a proven proprietary impact crusher design for achieving a high throughput capacity.

RM Release System

Keep crushing longer by resolving blockages with the touch of a button on your radio remote control.

Operate with the Touch of a Button

The RM 120X mobile impactor is built to make the most burdensome parts of crushing easy. Its modern information display, performance indicator, and total remote-controlled operation help you get the job done effortlessly. RM XSMART telemetry gives you more insights and clarity about your operation's efficiency, documents performance data, and enables you to troubleshoot issues faster.

Total Crusher Control

All functions are on your radio remote control.

Operator Assistance

Instant visual response on crushing performance, automated feed control and emergency machine shutoffs.

Easy Troubleshooting

Fault codes with easy to understand on-board resolutions.

Performance IndicatorX

Overfeeding or underfeeding your crusher slows you down. The Performance Indicator visualizes the utilization of the machine and helps operators find the sweet spot so that they can maximize production and improve their feeding skills.

Track & CrushX

You are in a pinch if you don't have a conveyor and wheel loader on-site. RUBBLE MASTER mobile impactors can be moved while crushing so that you can windrow your material and keep crushing.

Status LightingX

Status lights show the condition of the machine.

- Green - in operation / ready to crush

- Yellow - not ready to be fed or the machine is being moved

- Red - not ready because there is an issue

Load dependent feed speedX

The RM 120X mobile impact crusher regulates the feed speed according to the crusher load to maximize production and reduce the risk of stalling your crusher.

RM XSMART Telemetry Provides More Intelligence About Your Operation

Access machine telemetry and track tonnages conveniently on your cell phone or computer (optional belt scales).

Your safety is important to us.

This is why we keep your feet on the ground.

Climbing ladders with power tools and heavy parts is a safety hazard. All RUBBLE MASTER mobile impactors are fully ground serviceable, which makes light and safe work out of your daily maintenance.

Produce a Cleaner End-Product. Automatically.

The optional wind sifter uses an adjustable air stream to segregate lightweight debris, such as roots and fabrics. Without the wind sifter, you must manually pick contaminants and interrupt your operation more often to clean your screen deck. Improve your bottom line with aggregates people wait in line to buy and less labor involved.

Make more money per produced ton with diesel-electric mobile impactors

RUBBLE MASTER has been utilizing diesel-electric drives for its mobile crushers since our beginning in 1991. This well-proven system offers many benefits over conventional diesel-hydraulic drives - most notably its significant lower fuel consumption and surprisingly low noise emissions.

Save Up to 25% on Fuel

Our diesel-electric direct drive burns less fuel compared to traditional diesel-hydraulic tracked impactors.

Works Well in Extreme Temperatures

No heating up of hydraulics in winter and no overheating in summer.

Cut Hydraulic Fluid Costs

Our small hydraulic system is used for auxiliary functions only. Say goodbye to bursting hoses, leaks, and DEP/MOE citations.

Go Anywhere, Anytime

Experience the freedom of folding up your machine and going anywhere you want. The RM 120X, like all RUBBLE MASTER mobile impactors, was designed with mobility in mind making it easy to move.

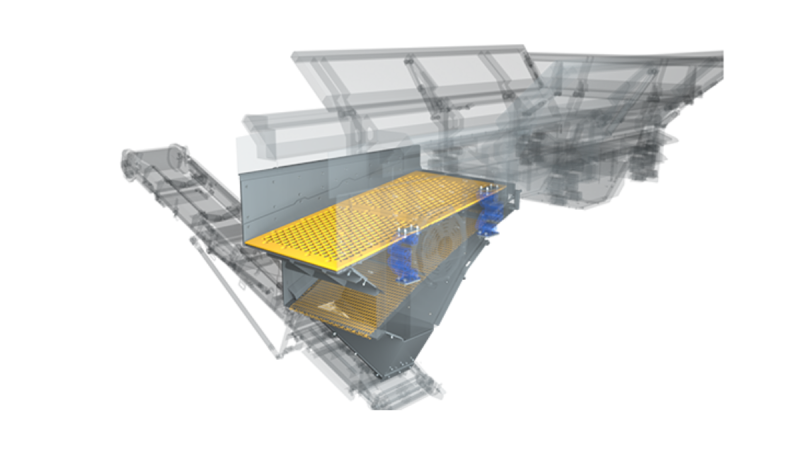

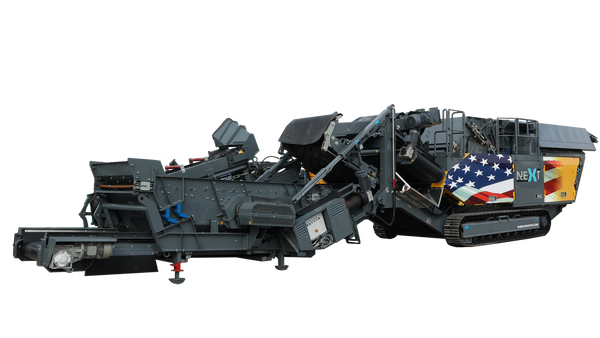

Easy to Detach Screen Attachment

You can break down the machine and move the bare crusher if required. The screen and return conveyor are entirely removed from the crusher.

15 Minutes From Trailer to Crushing

A single operator can get the crusher ready without the need of special hand tools.

Single move

Unlike other mobile impactors in this class, the RM 120X can be moved with the screen attached, saving valuable setup and breakdown time.

Video Gallery

RM 120X Specs

| Capacity | up to 350 tph up to 385 TPH |

| Inlet opening | 1,160 x 820 mm 46" x 32" |

| Ideal feed size | 660 mm 26 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 4 m³ 5.2 yd³ |

| Feed unit (extended) | 5 m³ 6.5 yd³ |

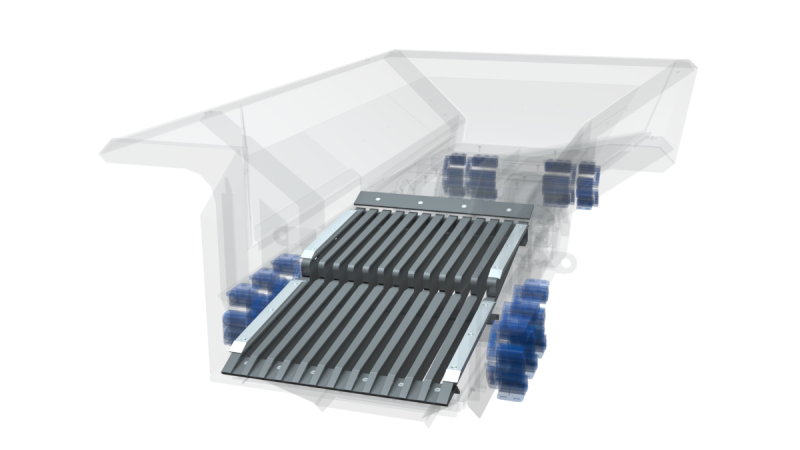

| Prescreen Grizzly (standard) | 1,560 x 910 mm 5.3 x 3 ft |

| Active Prescreen (optional) | 2,000 x 1,050 mm 6.5 x 3.5 ft |

| Screen-box | 1,480 x 3,708 mm 5 x 12 ft |

| Drive | diesel-electric diesel-electric |

| Transport dimension | 16,180 x 2,990 x 3,600 mm 52‘10” x 9‘11” x 10‘6“ |

| Weight (no options) | 44,000 kg 95,000 lbs |

| Weight incl screen attachment | 39,000 kg 86,000 lbs |

Operating a RUBBLE MASTER

is just…awesome.

Don’t just take our word for it.

"RUBBLE MASTER's design is highly efficient, to the point where other brands have attempted to copy it. The efficiency of RUBBLE MASTER is unparalleled in the industry. Additionally, the mobility is a crucial feature."

Nathan Henrich, Flatrate, United States

"If we couldn't crush this material on-site, this job alone would've created over 300,000 tons of excess material "

Eric Bruno, Midwest Crushing and Recycling, United States

Talk to an Expert

Have a question? Fill out the form, and a material processing expert will be in touch with you as soon as possible.