Dominate the Jobsite With a RUBBLE MASTER Concrete Crusher

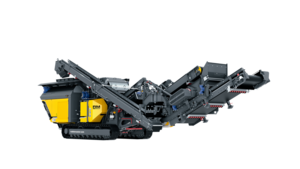

Mobile concrete crushers for processing concrete building slabs, bridgedeck, sidewalk, curbing, pipe, and high PSI runway concrete.

Dominate the Jobsite With a RUBBLE MASTER Concrete Crusher

Mobile concrete crushers for processing concrete building slabs, bridgedeck, sidewalk, curbing, pipe, and high PSI runway concrete.

Turn your concrete into cash with a mobile concrete crusher.

High-quality aggregates for a high-quality operation.

Increase Profits

Eliminate disposal fees. Reduce trucking costs. Create your own stockpile of valuable, gradable, and compatible material. Whether you save it or sell it, crushing your concrete will increase your profits.

Minimize Downtime

Simple and fast processes keep you crushing longer so that you put more product on the ground in a day.

Scale your Business

Whether you add a custom crushing profit center or just want to recycle your material RUBBLE MASTER has the right size machine to support your venture.

That pile of concrete is costing you money.

Whether you dump it or have someone else crush it, you’re losing profit. With a RUBBLE MASTER concrete crusher, you don’t have to depend on anyone else to get the job done.

You should get to spend your time dominating the jobsite, not waiting in line at the recycle yard.

Concrete Crushers for Producers and Contractors

Maximize your profits while minimizing downtime.

High Performance

RUBBLE MASTER mobile crushers provide the best throughput capacity in their class without sacrificing mobility.

Easy to Use

Operating a crusher doesn’t have to require years of experience. Our crushers make material processing easier than ever, so you can put any operator on your RUBBLE MASTER with confidence.

Safe to Use

Safety is our top concern so that you get back to your family safely.

New to crushing? We’ve got you.

At RUBBLE MASTER, we don’t just care about the equipment - we care about what our equipment does for your team and for your bottom line.

We believe you shouldn’t have to keep losing money to high operation costs or wasting time with traditional material disposal processes. That’s why we help you take back control of your operation and dominate the jobsite with mobile crushers that make you money.

3 Steps to Own your RUBBLE MASTER

Get The Equipment

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Get The Training

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Get It Done

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not hauling material or fixing your machines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

When material quality counts,

count on RUBBLE MASTER

RUBBLE MASTER's mobile impact crushers can be configured to meet any spec so you can tackle more jobs with a single machine.

Meet Your Spec

High-quality recycled concrete aggregates with excellent gradation for base and sub-base materials.

High Reduction Ratio

Our line of mobile impact crushers are ideal for producing smaller specs that require dust and fines for compaction.

Superior Compaction

Crushing process creates a gradeable and compactable material.

Job requirements change. So does your crusher.

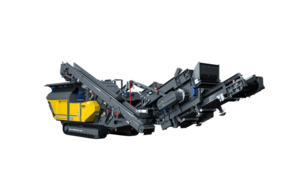

Produce more finished products with one machine.The on-board screen and return conveyor offer more versatility without adding screening equipment.

Fast Setup Change

Switch from open to closed circuit configuration within minutes.

Wide Range of Products

Crush a variety of materials and finished specs.

2-Way Split

Produce a screened product and an oversize product at the same time.

Built to Last

We know concrete doesn't come in convenient sizes or shapes. That’s why we built a mobile impact crusher that ensures smooth material flow and simple processes. When things go south, you can keep crushing without a headache.

Rebar Liberation & Segregation

Clean end product for a higher value commodity.

Smooth Material Flow

Little chance for rebar and contaminants getting hung up.

Automated Shutdown

RM impact crushers recognize jams and shut down conveyors before major belt damage can occur. This means you avoid long downtimes.

Our concrete crushers keep crushing with the touch of a button

Oversized concrete slabs can interrupt production. The RM Release System can undo a blockage by simply pushing a button on the wireless remote to keep crushing and put more product on the ground.

Application Videos

Ideal for Onsite Concrete Crushing

Many mobile crushers are heavy and burdensome to mobilize between jobs. RUBBLE MASTER Compact Crushers are easy to move so that you get the freedom to use your crusher at virtually any jobsite - small or large.

Easy to Mobilize

Move the crusher from site to site with ease.

Fast Setup

From trailer to crushing in 15 minutes.

Single Move

Crusher and screen attachment can be mobilized on one trailer

Our Concrete Crushers are Ideal for On-Site Crushing and Custom Crushing

“What makes a RUBBLE MASTER a RUBBLE MASTER? It would be the uniqueness of the compact size and the remote controlled operation combined with the diesel-electric power and high output we achieve with these machines.”

Dave Schielein, Ironhustler Excavating

Contractors Start Out with a Small Concrete Crusher and Grow into Our Bigger Models

"The thing that I like the most is how simple it is. Even it is a very high-tech machine it is easy to deal with. It is not overwhelming. My operators have caught on very quickly."

Nick Hooper, Dependable Demolition

Talk to an Expert

Since 1991, we’ve established ourselves as the world’s leading crushing & screening experts. Our products are used by the most cutting-edge contractors and aggregate producers worldwide.