Dominate Your Jobsite With a RUBBLE MASTER Limestone Crusher

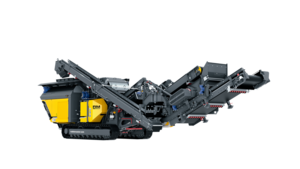

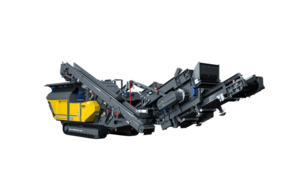

Mobile Jaw & Impact Crushers

Dominate Your Jobsite With a RUBBLE MASTER Limestone Crusher

Mobile Jaw & Impact Crushers

Turn your limestone into cash with a mobile crusher.

Limestone is an easy to crush sedimentary rock that is a soft to medium-hard. Crushed limestone has a variety of uses from dense graded aggregates (DGA) to aggregates for concrete and asphalt materials.

Increase Profits

Proprietary high-performance crusher box suitable for rock crushing and recycling. Fuel-efficient diesel-electric drives. Array of performance enhancing options available.

Minimize Downtime

Simple and fast processes keep you crushing longer so that you put more product on the ground in a day.

Maximize Utilization

Do more jobs with a single highly-mobile crusher. Crush limestone and recycle materials. Increase your return and pay for your crusher faster.

If your limestone crushing operation is down you are losing money.

Without easy to operate equipment you’re wasting man hours on repairing equipment, you are overwhelmed by the complexity, you are eating away at profit margin with outdated processes, and the growth of your company is being held back.

Crush Limestone Efficiently with Less Hassle

Maximize profits. Minimizing downtime.

High Performance

RUBBLE MASTER mobile crushers provide the best throughput capacity in their class without sacrificing mobility.

Easy to Use

Operating a crusher doesn’t have to require years of experience. Our crushers make material processing easier than ever, so you can put any operator on your RUBBLE MASTER with confidence.

Safe to Use

Safety is our top concern so that you can trust your guys around the machine.

When aggregate quality counts,

count on RUBBLE MASTER impact crushers

Mobile impact crushers feature a high reduction ratio and produce consistent cuboid aggregates. Meet your spec with multiple crusher settings and an on-board screening plant and return conveyor (closed circuit impact crusher). In many cases, crushing limestone does not require a primary jaw crusher! (we offer jaw crushers as well)

3 Steps to Own your RUBBLE MASTER

Get The Equipment

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Get The Training

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Get It Done

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not hauling material or fixing your machines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

Make more money per produced ton with diesel-electric crushers

Operating costs affect your limestone crushing operation. Diesel-electric drives are more efficient so that you can save on fuel, hydraulic fluids, and maintenance to increase your crushing profits.

Large range of mobile screening plants for aggregate producers

If one machine is not enough we can provide you mobile screening plants, rinser screens, and stacking conveyors to maximize your production and optimize your limestone crushing operation.

Application Videos

We can crush hard limestone with an impact crusher

Occationally, limestone can be very hard and difficult to crush. Where most other mobile impact crushers fail RUBBLE MASTER's revolutionary mobile hard rock crusher can do the job. The RM V550GO! is an impactor designed for difficult applications, so that you can reduce your machine investments and increase your profits. Primary crusher, secondary crusher and screener in one machine.

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.