How to order aggregate replacement screens for your mobile screening plant?

Everything you need to know before you call.

Avoid waiting for call-backs and get important facts faster so that you minimize downtime, and maximize production.

Reduce blinding, pegging, premature wear, and navigate the material processing minefield successfully.

A smooth material flow and improved throughput yield more profits.

Screen media can make a difference between 100 TPH and 200 TPH. You often find yourself resolving issues rather than feeding the screening plant. In the worst case, your finished product is contaminated, and your hard work is wasted.

Specify opening or mesh count, screen type, wire diameter and alloy required (stainless steel, high carbon / low carbon alloy).

Depending on the aggregate you’re screening, you chose your alloy. High carbon screens struggle with processing wet materials because of the likelihod of sticking. Stainless steel has proven to be better for sticky or wet materials. The overall weight of the feed material and corrosiveness also have an impact on the wire diameter. The heavier the material the thicker and heavier the screen media.

Your screening expert can help you with sepcifying the aggregate replacement screen. The aim of the game is to maximize surface aperture without limiting your wear life and strength so that material can pass through. The open area varies with the screen media type and affects your screen capacity.

The more open area the more screening capacity

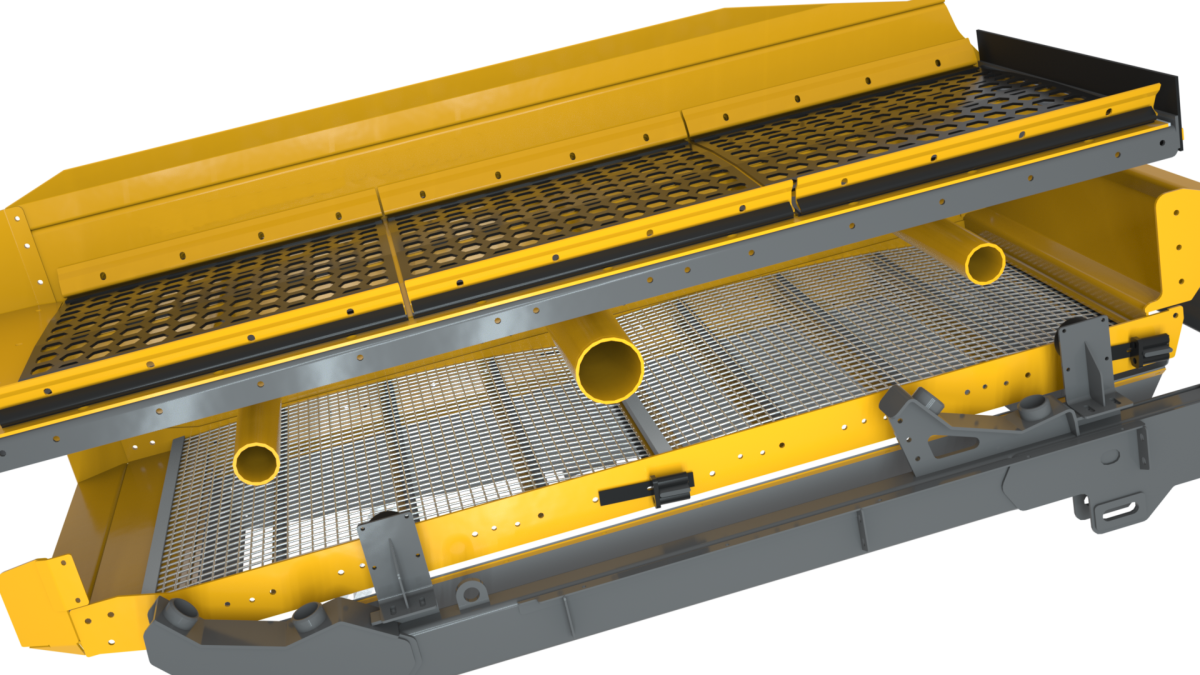

On mobile screening plants with mutliple decks such as on scalping screens or incline screens, the relation of open area and material gradaition between the decks needs to be balanced.

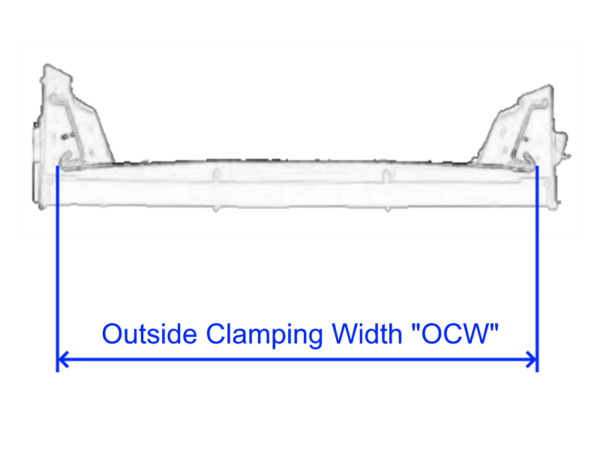

Provide the finished dimension of each screen panel and number of panels required. Keep in mind that not all panels are the same size on mobile material processing plants. Mobile screening plants often use flat screens with hooked edges. You need to determine the screen length and its OCW (outside clamping width) or ICW (inside clamping width) in inches.

To get the dimensions you can...

If a slotted opening is required, the direction of the slots should be specified in relation to the hook strips. Number of shoot wires should also be specified (most common is single shoot and triple shoot).

Specify the hook types and material, and advise any special conditions such as : end tension, welded hooks, one hook up & one hook down or 2 hooks up.

Proper screen size and tensioning are critical for effective screening and longer screen life. Banded edges strengthen hooked edges and provide even tensioning across the screen.

Proper screen size and tensioning are critical for effective screening and longer screen life. Banded edges strengthen hooked edges and provide even tensioning across the screen.