Top 5 Impact Crusher Parts You Should Keep on the Shelf

Minimize downtime. Maximize profits.

Mobile crushing contractors and aggregate producers know that when your mobile impact crusher is down, your crew is down, and you are bleeding money. That's why they invest into a support infrastructure, parts inventory, and a strict maintenance schedule.

Without keeping key impact crusher parts on the shelf, you…

Hammers (blow bars) wear out over time or can break when hitting an uncrushable object. If you don't change worn-out or damaged hammers in time, you start damaging your rotor body. This means you must change hammers on the spot to avoid costly rotor damage and an even more lengthy machine downtime. Therefore, keeping a spare set in your service truck or on the optional hammer bracket is highly recommended.

Please note that hammers must be changed in pairs due to weight balancing on the rotor.

Learn more about various types of hammers in this article.

If your impact crusher is jammed, the fuse burns, releasing the hydraulic fluid in your hydro coupling to disengage the engine from the rotor. This prevents costly damage to your engine assembly. If this happens, you need to clear the blockage, replace the fuse, and top up the hydraulic oil to continue. The fuse is a small, inexpensive part that can be replaced easily. By default, RUBBLE MASTER delivers a spare fuse plug in your toolbox, but it is advised to restock one immediately if used.

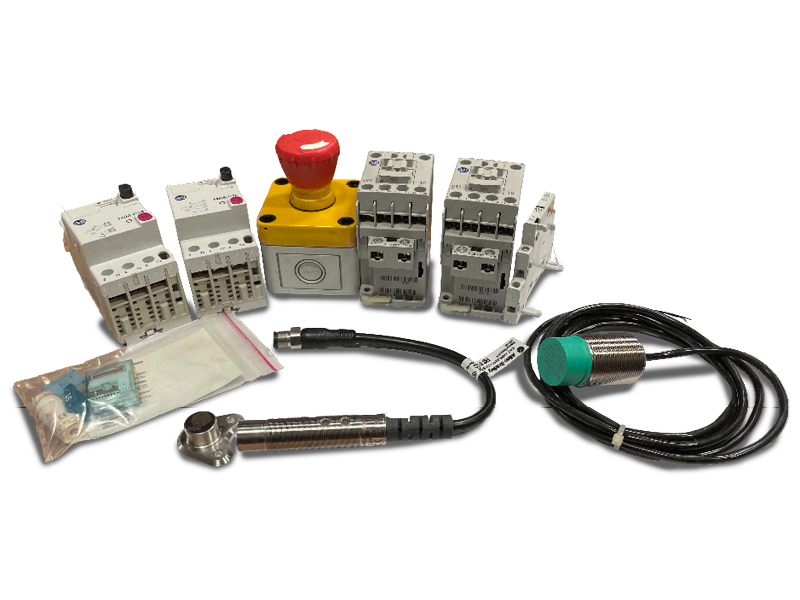

An electrical emergency kit should include various types breakers, fuses, and a proximity sensor. Breakers, fuses, and sensors shouldn‘t fail but it can happen. In case this happens, they are readily available, cheap and easy & quick to ship. So why keep them on the shelf? They are cheap and you can swap them quickly yourself without wasting any time. Thus, this is a must have for anybody who needs maximum uptime.

When the airfilter gets dusted your engine can be seriously damaged. Therefore you should tap out or gently blow out your air filter regularly. If dust is visible at the safety cartridge it is recommended to change both – airfilter and safety cartridge.

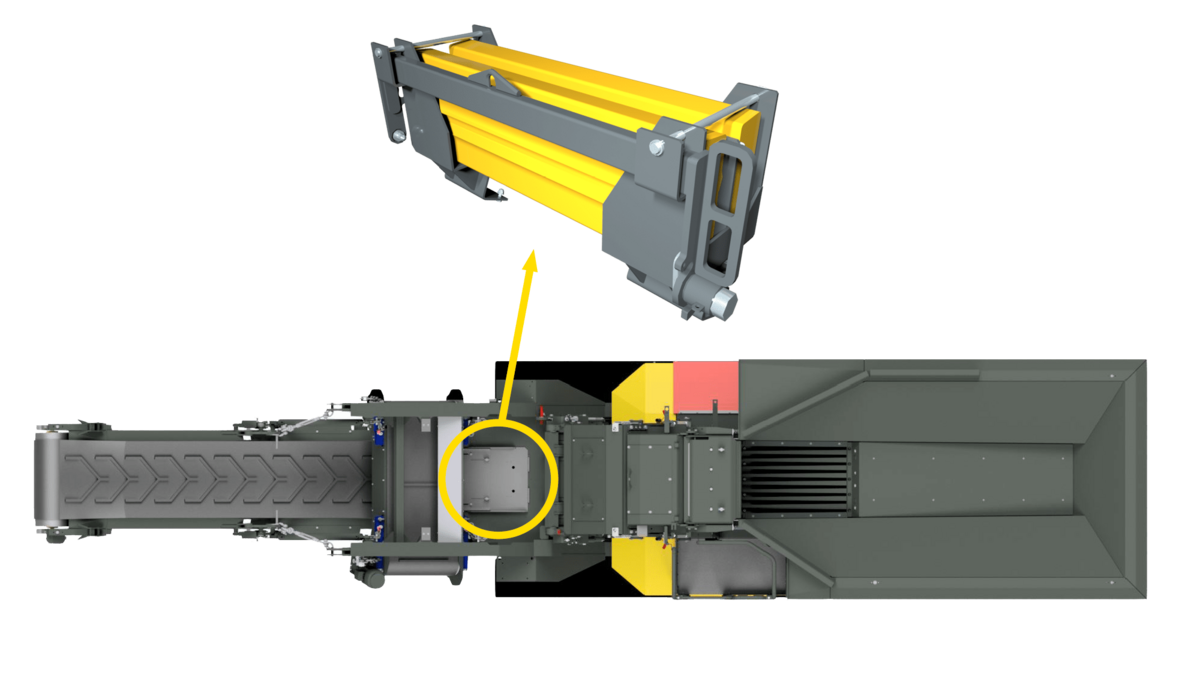

Side liners (also called wear plates or cheek plates) are Hardox plates that armour the crushing chamber on the sides and wear out over time. The pace of wearing out depends on their location inside the crushing chamber. It is recommended to keep the side liners in the high impact areas on the shelf so that you can change them easily and quickly when needed.

Please keep in mind to also order the wear bolts and washers.