River Gravel Crushing Made Easy

River Gravel Crushing Made Easy

Few materials are as demanding as river gravel: it is extremely hard, highly abrasive, and usually requires several crushing stages to achieve the required cubic final aggregate. For many contractors, this means more machines, more transport, and more maintenance.

One machine, one pass – instead of several crushers

Traditionally, producing high-quality cuboid aggregate from river rock requires at least a jaw and a cone crusher. The RM 100GO!, however, achieves the same result in just one pass with its integrated mesh screen. For Quilín, this means:

Less investment

one machine instead of a line of crushers

Lower operating costs

reduced wear parts, fuel, and manpower

Simpler logistics

only one unit to move, even to remote job sites

Perfectly cuboid aggregate – every time

River gravel is used in demanding applications such as airport substructures, where cubicity and consistent quality are non-negotiable. Thanks to RM’s impact technology and adjustable crushing box, Quilín can now reliably deliver perfectly cuboid final aggregate that meets specification.

"The RM 100GO! is a very simple machine to operate. It is easy to maintain and configure, so we always manage to deliver a final aggregate with well-defined edges that meets requirements."

— Quilín Team

Easy transport – even to remote Patagonia

From Santiago to Puerto Aisén, more than 1,700 km away, the RM 100GO! proved its flexibility. Transported by low loader and even driven on and off ferries by remote control, the crusher made the long journey without delays or complicated logistics. For contractors like Quilín, saving transport effort means saving time and money.

Customer success speaks for itself

"We are very satisfied with the performance of our Rubble Master RM 100GO! crusher. We can truly testify that this equipment has been an excellent addition to our projects throughout Chile. Its efficiency, robustness, and ease of operation have significantly improved our productivity on-site. We highly recommend it for large-scale projects."

José Tomás Schenke Reyes, Machinery Manager, Quilín, Chile

Crushing river gravel – the easy way

For Quilín, the RM 100GO! means fewer machines, lower costs, and reliable results – even with the most demanding material. And that’s what makes the difference: turning one of the toughest crushing challenges into a smooth, efficient process.

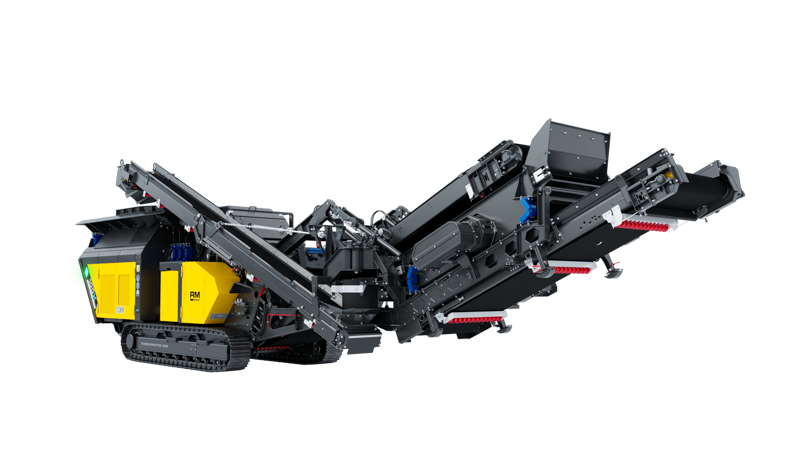

RM 100X Specs

| Capacity | up to 250 tph up to 275 TPH |

| Inlet opening | 960 x 700 mm 38" x 28" |

| Ideal feed size | 560 mm 22 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 3.3 m³ 4.3 yd³ |

| Feed height | 3,000 mm 9' 10" |

| Prescreen Grizzly (standard) | 1,500 x 900 mm 4'11" x 2'11" |

| Screen-box | 1,300 x 3,000 mm 4 x 10 ft |

| Drive | diesel-electric diesel-electric |

| Transport dimension | 14,700 x 2,860 x 3,160 mm 48'2" x 9'4" x 10'4" |

| Weight (no options) | 31,000 kg 68,350 lbs |

| Weight incl screen attachment | 35,810 kg 78,950 lbs |