Crushing and screening iron ore is a demanding task. The material is heavy, abrasive, and processed in large volumes—often under tough conditions. At the Lion Mining Group mine in Piripiri, Piauí (Brazil), RUBBLE MASTER mobile crushers and screens are proving their strength every day.

Since June 2025, Lion Mining Group has been using a RUBBLE MASTER train to process iron ore for steel production in Brazil and China—turning raw material into steel sheets with consistent results.

The Machines Behind the Success

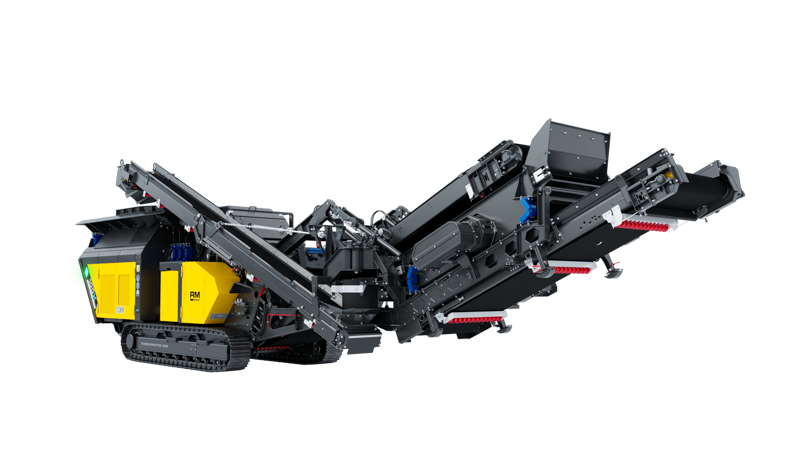

The operation handles feed sizes up to 600 mm, producing three key fractions: 0–10 mm, 10–15 mm, and 15–32 mm. To achieve these precise sizes, the mobile RM setup combines the heavy-duty scalping screen RM HS11000M, the impact crusher RM 100GO!, and the precision screen RM MSC8500M-3D.

The processed ore is shipped to steel mills in Brazil and China and used in the production of steel sheets.

Mining with Mobile Impact Crushers

Traditionally, jaw and cone crushers dominate in mining aplications. But impact crushers—especially in mobile configurations are proving their worth, offering:

High reduction ratios for multiple size fractions

Fast & simple maintenance

Mobility for remote sites

Consistent Production in a Demanding Environment

The site is operated by Edycarlos, an experienced contractor who already owns several RUBBLE MASTER units. He values the ease of use and reliability of RM machines, especially in high-output mining environments.

“We’ve been able to maintain a good daily operating rhythm thanks to the easy handling, maintenance, and mobility of the RM machines across different job sites,” says Edycarlos.

While the main challenge has been sourcing specific spare parts quickly within the Brazilian market, the team appreciates the long-term support and direct contact with RUBBLE MASTER and our local partner Maquina Solo.

More RM Machines in Action

In his operations, Edycarlos relies on further RM crusher and screener models such as the jaw crusher RM J110X the impactor RM 120X and the sizer screen RM MSC10500M-3D. These machines give him the flexibility to adapt quickly and achieve efficient production under varying conditions.

RM 100X Specs

| Capacity | up to 250 tph up to 275 TPH |

| Inlet opening | 960 x 700 mm 38" x 28" |

| Ideal feed size | 560 mm 22 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 3.3 m³ 4.3 yd³ |

| Feed height | 3,000 mm 9' 10" |

| Prescreen Grizzly (standard) | 1,500 x 900 mm 4'11" x 2'11" |

| Screen-box | 1,300 x 3,000 mm 4 x 10 ft |

| Drive | diesel-electric diesel-electric |

| Transport dimension | 14,700 x 2,860 x 3,160 mm 48'2" x 9'4" x 10'4" |

| Weight (no options) | 31,000 kg 68,350 lbs |

| Weight incl screen attachment | 35,810 kg 78,950 lbs |