How to Bid for Crushing Concrete

Methods and Pricing

When it comes to concrete crushing, not every job is the same. The size, complexity, and scope of the project significantly influence your concrete crushing bid strategy. Whether you're dealing with large-scale commercial demolition or smaller residential concrete recycling, understanding the nature of the job is crucial.

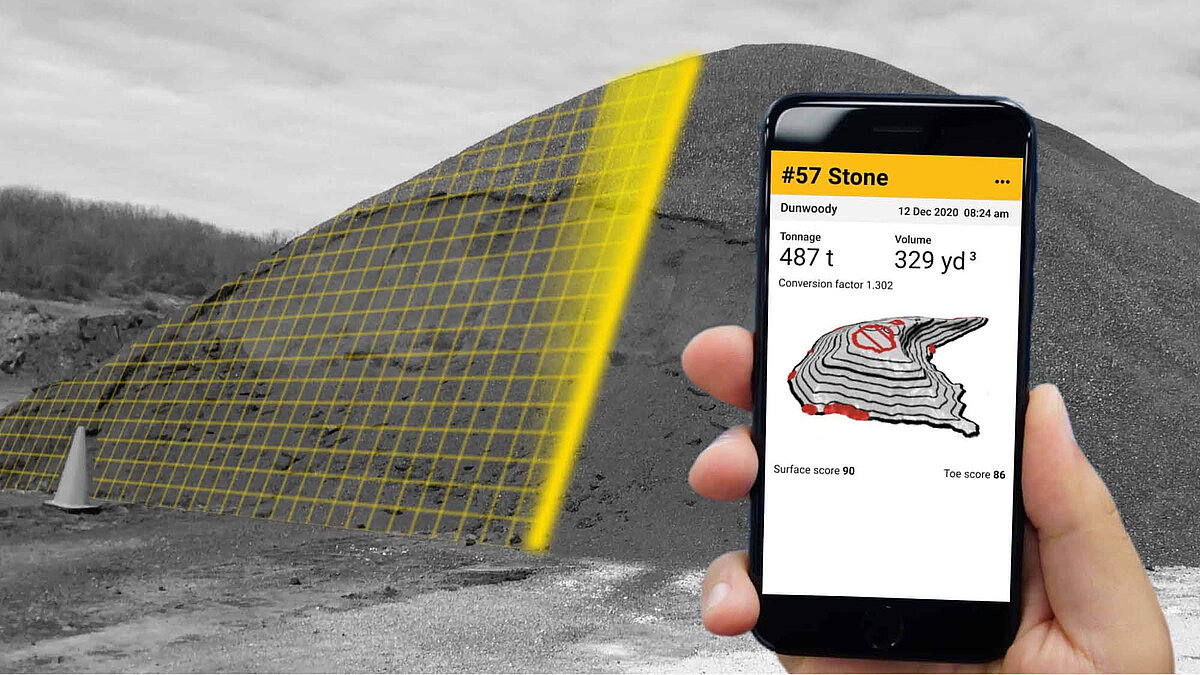

To understand the material volume of a pile, you can walk the pile and make an estimate or use tools such as SR Measure or similar drone-based systems.

High-volume concrete crushing projects demand heavy-duty machinery and are typically highly competitive. Success often hinges on your ability to deliver lower cost per ton while maintaining productivity and efficiency.

These jobs involve:

Concrete crushing starts with material prep. Whether using a mobile impact crusher or jaw crusher, you must ensure proper preprocessing. Clear roles need to be defined:

💡 Tip: Plan for a full day of prep for every full day of crushing unless conditions suggest otherwise.

If you are responsible for prep, you must factor in an excavator and concrete pulverizer to preprocess the material. For certain crushing jobs, using a primary jaw crusher before your mobile impact crusher might be worthwhile to reduce wear and maximize production.

If you are responsible for concrete prep, you should consider a full day of material prep for a full day of crushing. This may change depending on the material you need to process. You are losing money if you stop crushing to pre-process some more concrete.

Moving crushed concrete efficiently is critical to avoiding downtime.

Options:

Ensure your bid reflects who provides and operates the loader. If the client supplies the loader, specify machine capacity requirements to avoid delays from underpowered equipment.

A tracked conveyor is typically more reliable and consistent than a wheel loader. A wheel loader might be required because of logistics or the available room. In this case, you must communicate clearly with your client who provides the loader.

If your client insists on using his loader and operator, you should communicate clearly what size machine is required. Sometimes, contractors keep their weakest machines in their yards, which can slow you down and affect your bottom line.

When crushing concrete, you end up with a lot of liberated rebar —a valuable scrap material. You should account for having a bin at the job site to collect rebar or discharge the rebar directly into the bin. This can be a nice pocket money at the end of the day.

Your contract should clearly state

Making an estimate is difficult if you have no control over the material and don’t know what’s in the pile. If you lack experience estimating concrete crushing jobs, you can keep the material prep and the actual concrete crushing separate.

For the material prep, you could offer an hourly rate for an excavator, operator, and pulverizer, while for the actual concrete crushing, you can offer a cost-per-ton rate.

In your crushing rate, you should factor in:

To bill your customer for the crushing job, you will need a belt scale on the crusher or stacking conveyor to provide proof of your service. The RUBBLE MASTER proprietary belt scales are tied into the RM XSMART Telemetry system, providing an easier belt scale control and advanced reporting functionalities. Optionally, you can also install belt scales from a third-party supplier such as Beltway Scales.

Small concrete crushing jobs—such as a few hundred tons—are less competitive but require a different bidding mindset. Instead of competing on price per ton, emphasize the value of on-site concrete recycling. Typically, you solve a specific problem related to material disposal or available room.

Therefore, you need to understand your customer's pain points:

To craft a winning bid:

Then, offer a crushing service at a price just below total disposal and hauling costs, creating a win-win scenario.

💡 With RUBBLE MASTER Compact Crushers, your low mobilization cost and high efficiency make you highly competitive—even on small jobs.

You should add the cost to move the equipment in and out on top of the crushing costs. The beauty of RUBBLE MASTER Compact Crushers is that it takes 15 minutes from trailer to crushing, giving you a competitive advantage over many other crushers that require multiple truckloads and hours of setup and tear down.

The rapid deployment of those machines allows you to be very competitive with large jobs because you have produced several thousand tons of material before others even start, and you dominate smaller job sites where high mobilization costs kill crushing economics.

Every crushing project is unique. Site visits help you evaluate:

Look for red flags:

If the concrete pile was buried somewhere and is overgrown, you might want to use a mobile scalping screen before your crusher to segregate dirt from the feed to minimize wear and produce a better end product.

Clear communication about your crusher’s capabilities—especially with rebar size and material type—will protect your equipment, crew, and bottom line.

Whether you’re tackling a high-volume commercial concrete recycling project or a small on-site concrete disposal job, your bid must reflect:

With clear communication, accurate cost breakdowns, and a strategic value proposition, you’ll not only win more concrete crushing contracts—you’ll also maximize profit and performance on every job.

For more than 30 years, RUBBLE MASTER has been manufacturing premium concrete crushers that work in more than 110 countries worldwide. With our dense dealer network, we help contractors make more money with materials.