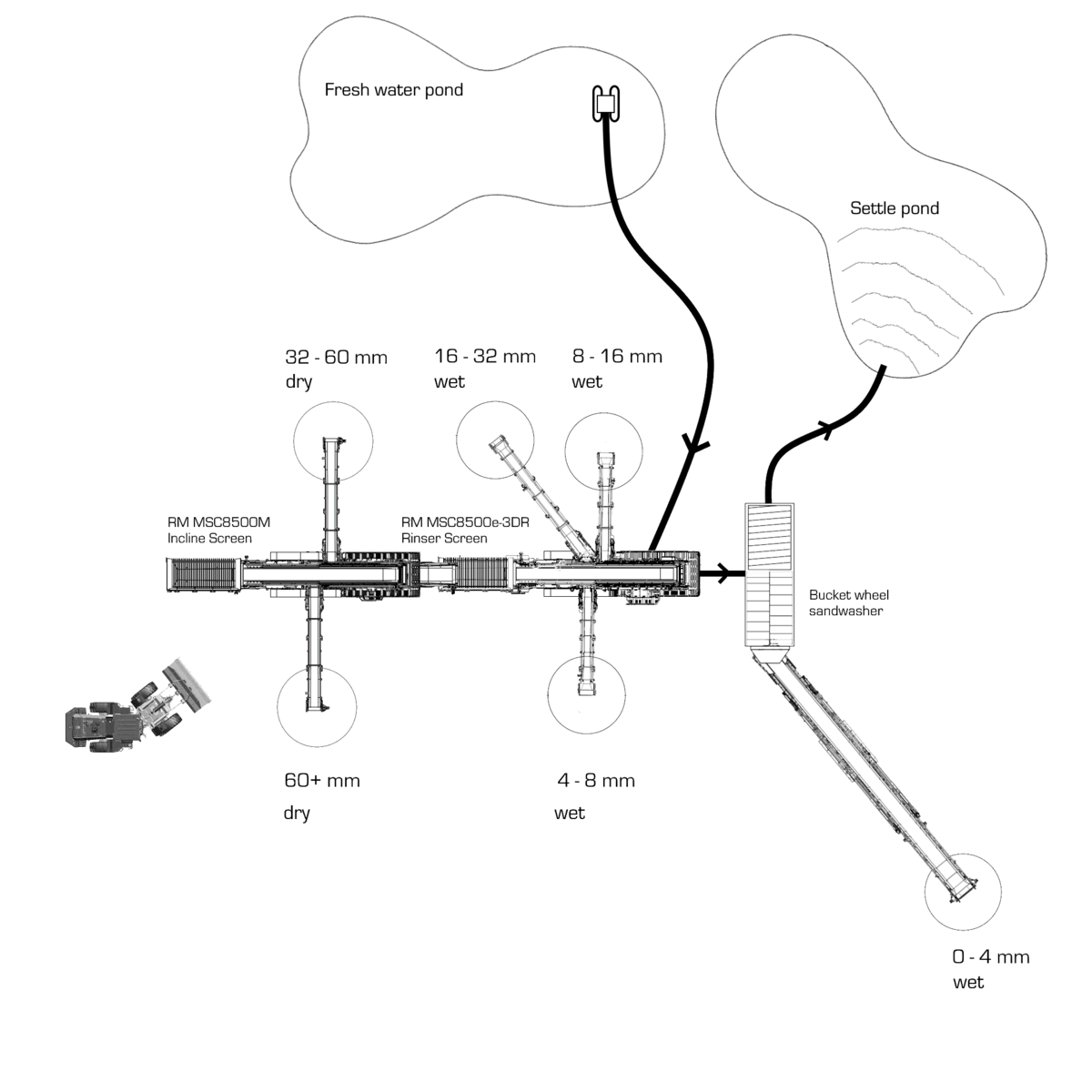

Traditional Washing Doesn’t Work for Every Pit

When you manage multiple pits, handle smaller material volumes, and face tightening regulations, stationary washing systems quickly become a liability. Add unpredictable demand, stormwater risks, and rigid infrastructure, and you’re stuck with a setup that’s costly, inflexible, and hard to maintain.