8 Items That May Break Your Impact Crusher Hammers

Broken impact crusher hammers are costly and result in unplanned downtime. Avoid feeding these uncrushable objects at all cost to maximize the utilization of your blow bars.

Compact impact crushers can process natural rock, concrete, and asphalt into aggregates for construction. However, certain materials (so-called uncrushables) cannot be crushed and can cause damages inside the crusher box and stop your production.

If you feed uncrushables in your compact impact crusher, anything can happen.

You can break a hammer on your impact crusher

You can bend your rotor shaft

You can damage conveyor belts

Increase wear

Being in control of your feed and material prep allow you to set uncrushables aside or avoid that uncrushables end up in your feed pile. Check out the blog post Small Rock Crusher Feeding Tips for Novice Operators. Here you can find more practical tips on how to operate a compact impact crusher.

Bearing Bracket

Bearing Bracket

Cannon ball

Cannon ball

Hydraulic hammer pin

Hydraulic hammer pin

Bucket tooth

Bucket tooth

I-beams & railroad rails

I-beams & railroad rails

Steel dowels in runway concrete

Steel dowels in runway concrete

Steel Slag

Steel Slag

Milling bit

Milling bit

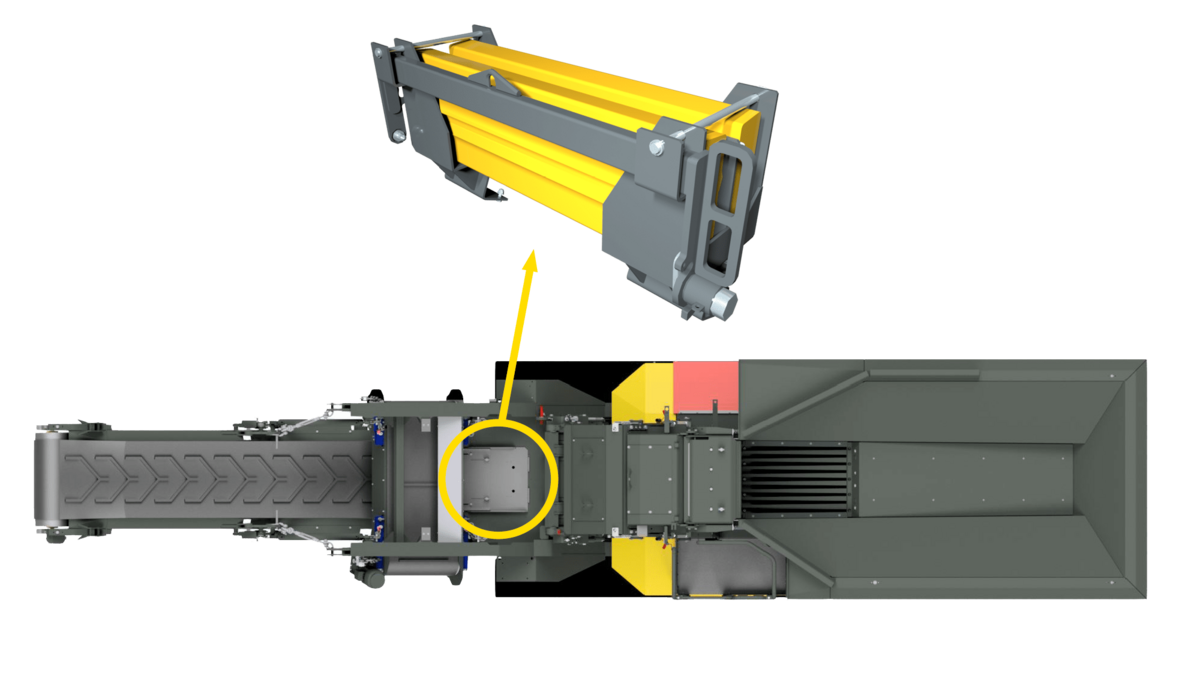

RUBBLE MASTER compact impact crushers feature the RM Release System to reduce the risk of major damages by allowing the force to be absorbed and the uncrushable to pass.

Oversized concrete slabs and uncrushables can interrupt production. The RM Release System features a spring-loaded impact wall that absorbs some of the force and allows the room to let materials pass more easily. It can also be activated by the touch of a button on your radio remote control to let over-size concrete pieces fall into the action radius of the rotor.

When your hammers break, you need to change the set (the broken hammer and the opposite hammer) immediately to avoid further damages to the rotor. If you don't have spare hammers available quickly you lose production and money. The optional hammer bracket allows you to keep a spare set of hammers on your compact impact crusher to reduce your downtime and hassle to get the hammers to the jobsite.

Consider the following scenario:

| Crusher production | 100 TPH |

| Downtime | 4 hours |

| Material value | 5 $/tons |

| Excavator cost | $150 per hour |

| Crusher cost | $250 per hour |

| Total cost of downtime | $3,600 |

| Theoretical hammer cost | $2,000 |

| Theoretical savings | $1,600 |