On-Site Recycling

Make More Money with Your Materials

Make More Money with Your Materials

Make More Money with Your Materials

Many new developments require the demolition of old structures, generating massive amounts of waste. Concrete recycling is a process of collecting and crushing concrete to produce a recycled concrete aggregate product for reuse or sale. The newly produced recycled commodity is much cheaper than comparable virgin aggregates.

Traditional methods of disposal are costly and time consuming. Recycle & reuse concrete on-site so no material needs to leave your site.

Produce your material at a much lower cost than purchasing your aggregates from a quarry or recycling yard.

Generate new sources of income for your business by selling aggregates and custom crushing.

Without concrete & asphalt recycling you lose money to expensive trucking and tipping fees, you waste time waiting for the trucks to show up, and get frustrated with the ever increasing hassle to dispose of materials.

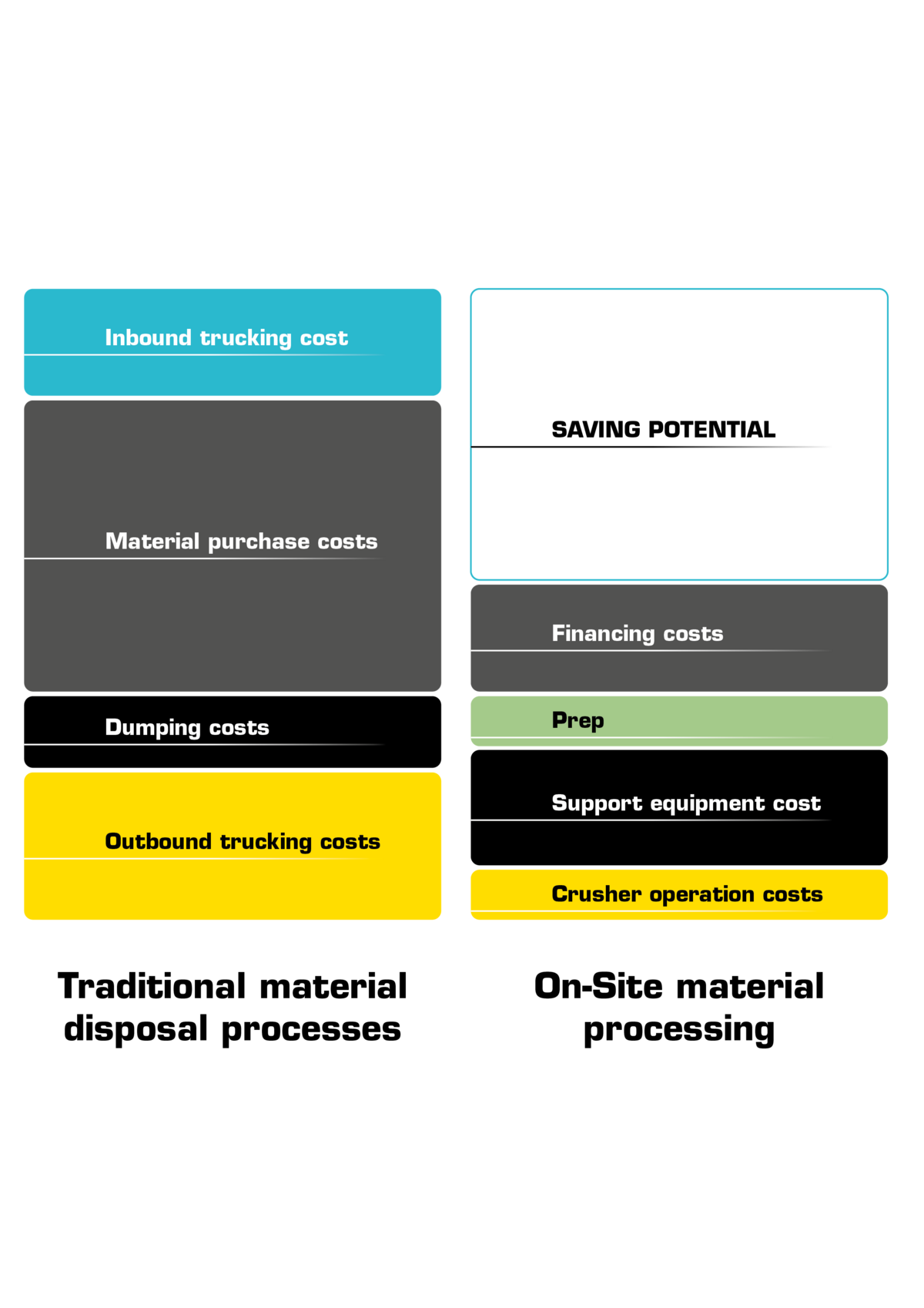

The asphalt & concrete recycling business model is a simple debit and credit calculation. You need to contrast your current material disposal and purchase processes with crushing your material on-site. Many contractors realize that investing in a crusher pays dividends fast and has many more benefits for your business, from additional income streams to added efficiencies in your processes.

* actual production costs depend on feed material, contaminants, fines, moisture, and many more factors. More cost factors apply. Consult your material processing specialist.

Don’t just take our word for it.

“I started crushing because I believed there is a future in that to get rid of the product. It is getting more costly to dispose of it. It is getting more expensive to truck it over the road with DOT and what not.”

Mike Reilly, F.P. Reilly & Sons Inc.

We want to give our customers the best product possible. Our biggest philosophy is, we want to leave a site cleaner than we found it. And that's what makes me enjoy what I do, recycling a product that was once thought of as a waste, let's make it into something that we can reuse.

Eric Bruno, Midwest Crushing & Recycling

"RM crushers are unbelievably flexible, easy to use and extremely powerful. Even customers who have never worked with a crusher before can now easily recycle materials to save on disposal and protect the environment. In a few weeks, we will be taking delivery of our third."

Paul Fot, Owner and Managing Director, FOT Machinery, Germany

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.