Dominate Your Jobsite with a RUBBLE MASTER Granite Rock Crusher

Mobile jaw and impact crushers for processing hard rock.

Dominate Your Jobsite with a RUBBLE MASTER Granite Rock Crusher

Mobile jaw and impact crushers for processing hard rock.

Turn your granite into MORE money!

Maximize production. Minimize downtime.

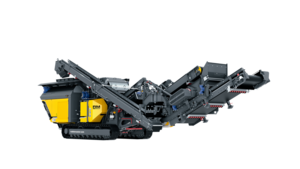

The Ideal Crushing Spread for Granite

RUBBLE MASTER offers mobile jaw & impact crushers, screening plants, and tracked conveyors.

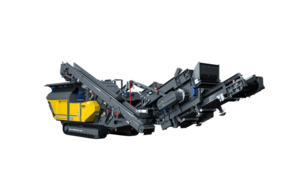

A New Experience Operating a Mobile Crusher

We make the most burdensome parts of rock crushing easy. Simple and fast maintenance processes keep you crushing longer so you put more product on the ground.

Trust Your Guys Around the Machine

Rest assured that you get the most out of your crushing spread. Safely.

You Work Too Hard to Waste Money to High Operating Costs

Machine down means crew down, and you are bleeding money. Whether you face a technical issue or lengthy maintenance procedures, you're losing profit. RUBBLE MASTER crushers are designed to make the most burdensome parts easy, so you get the job done faster with less hassle—thus minimizing your downtime and keeping crushing longer.

3 Steps to Own your RUBBLE MASTER

Get The Equipment

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Get The Training

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Get It Done

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not fixing your machines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

When material quality counts,

count on RUBBLE MASTER

Being out of spec is not an option.

Meet Your Spec

Produce high-quality aggregates people wait in line to buy.

High Reduction Ratio

Our line of mobile impact crushers are ideal for producing smaller specs.

Adjust as Fast as Your Job Requirements

Easy and fast change of screen media and crusher settings.

Application Videos

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.