Dominate your jobsite with mobile rock crushers that work as hard as you.

Mobile jaw & impact crushers for processing rock.

Mobile jaw & impact crushers for processing rock.

Mobile jaw & impact crushers for processing rock.

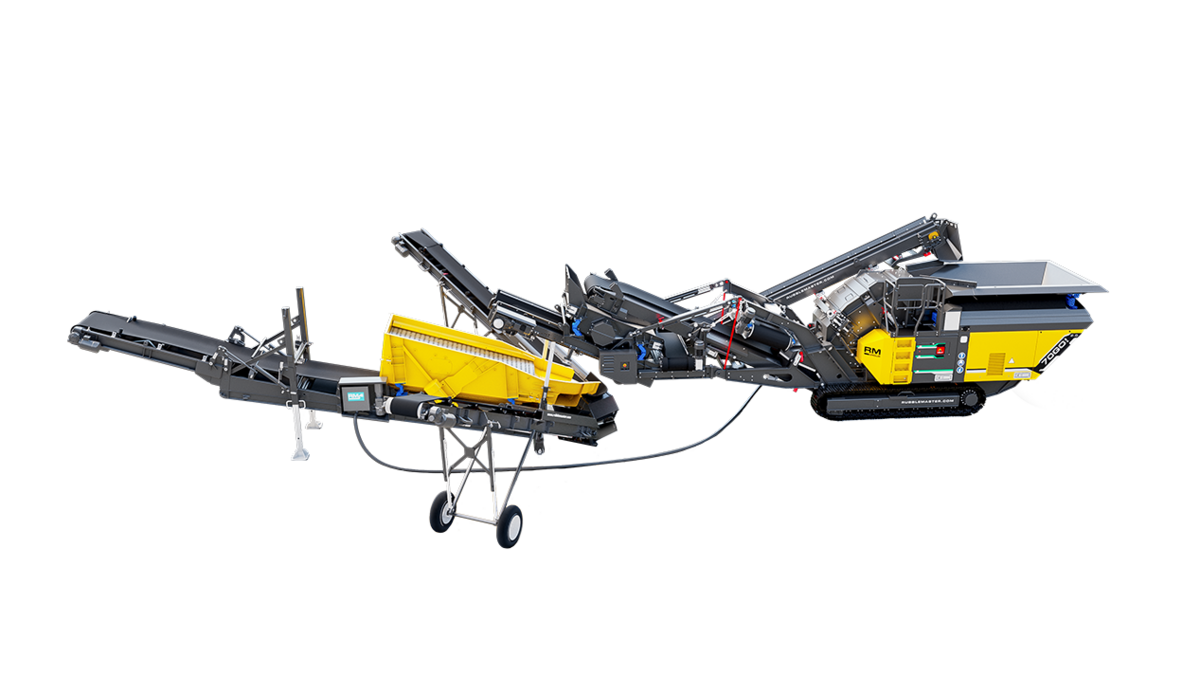

Whether you need to add crushing capacity or replace an existing crushing spread, RUBBLE MASTER has the right size rock crusher and screening plant to grow your business. Mobile jaw and impact crusher plants, screening plants, and conveyors.

RUBBLE MASTER rock crushers have been designed for efficiency and performance so you can make more money per man-hour. Our diesel-electric drives are maintenance friendly and burn less fuel.

We have a range of mobile rock crushers and screens available to produce the aggregates you need.

A new experience operating a mobile rock crusher. Make the most burdensome parts of rock crushing easy. Enjoy greater clarity through a new human-machine interface and RM XSMART telemetry.

Maximize profits. Minimizing downtime.

compared to traditional diesel-hydraulic crushers

Aggregate equipment is bulky, heavy, and difficult to move. RUBBLE MASTER machines are designed from scratch with mobility in mind, so you get the freedom to move anywhere and save transport costs.

Ultimately, the more you make per day, the more you make.

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not fixing your machine or dealing with lengthy daily maintenance routines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

Our diesel-electric crushers provide more power to run additional electric equipment such as the RM CS Compact Screen attachment, a water pump, or an electric stacking conveyor. Contact your RUBBLE MASTER expert for available power output and details.

Don’t just take our word for it.

“With the new RM 100GO! hybrid, we get a much better geometry of aggregate compared to the cone crushers we used to use. Asphalt adheres better and decorative chippings look better; essential criteria for our customers, who range from landscape gardeners and building contractors to private consumers.”

Jonathan Schaffers

Welbers Kieswerke GmbH

"I have about 12 RM machines and I am very happy with their performances. The high quality of the final material produced by the RM impactors really surprised me and helps tremendously to fulfill the given requirements. We use the RM crushers for base, subbase and aggregate production and in all of these applications they give us outstanding throughput and perfect final results. We have worked with many other crushers of all kinds before but none of them could give us the same quality of final material and efficiency like the RM machines."

Gabriel Meléndez

Grupo Indi

"The reason why we keep buying RUBBLE MASTER is service support. One thing that’s impressive is that you can call any of these guys, and they always pick up the phone. They might not have an answer, but even if they don’t have the answer, it doesn’t take days but hours to get it handled."

Nathan Henrich

Flatrate Inc

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.