Are you ready for a new eXperience?

Intuitive operation, digital intelligence, and maximum efficiency – so you can master every task safely, easily, and successfully.

Are you getting the most out of your crushing operation? → FREE WEBINAR: Crush Smarter: How to Optimize Your Setup and Maximize Profits with Mobile Impact Crushers - Jul 31

Get more done in a day.

Make better decisions.

Intuitive controls, built-in diagnostics, and automation make every operator a pro from day one.

If you don't have easy to use equipment, you...

Simplicity and safety increase efficiencies and profits.

Aggregate equipment is bulky, heavy, and difficult to move. RUBBLE MASTER machines are designed from scratch with mobility in mind, so you get the freedom to move anywhere and save transport costs.

Many machines require operators to climb ladders to access service points. RUBBLE MASTER equipment can be serviced with your feet on the ground, so that you are faster with your daily maintenance and reduce the risk of injuries.

You have to stay outside the safety perimiter while running your crusher. RUBBLE MASTER crushers are fully radio remote operated, so that you can control your cruhser conveniently from your cab and eliminate the need of running down a material pile every time you need to adjust a setting.

Stay aware of what’s happening around the machine to avoid downtime and keep your crew safe. That’s why RUBBLE MASTER provides clear visual feedback —so your team knows the machine’s status at a glance and can hit the optimal feed rate for maximum output.

At RUBBLE MASTER, we understand you want to feed the crusher. If you waste time with lengthy processes, you lose production and profits. Our service and daily maintenance routines are simple and intuitive (e.g. stickers for lube points and lube schedule) so that you can start crushing faster with less hassles.

Many jobs don't have enough material or room to justify mobilizing a stacking conveyor. RUBBLE MASTER Compact Crushers can track & crush simulateneously, so that you can windrow your material and keep crushing.

Once started a RUBBLE MASTER crusher can be controlled conveniently via the radio remote control. In many applications the crusher can be operated by one operator, so that you get the freedom to run on your own anytime without a ground man.

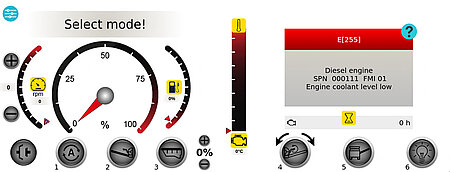

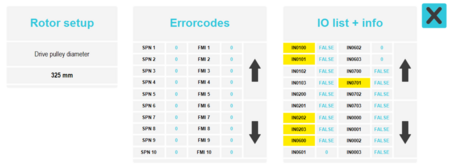

When issues arise on the jobsite, it can feel frustrating. That's why RUBBLE MASTER offers clear information, guides, and actionable first steps to help you become more self-sufficient and reduce the need for endless phone calls and wasting time waiting for someone to get back to you.

View the machine’s condition, troubleshoot issues, and adjust settings. If the radio remote control fails, all crusher functions can be operated via the touchscreen display.

Identify the issue and resolve common errors without a service technician or flipping through endless manual pages.

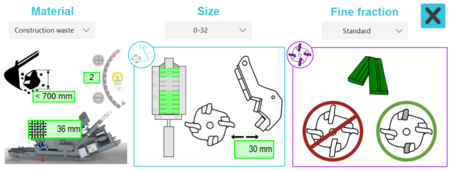

Initial setup tips to optimize production and reduce wear, without flipping through the manual or guesswork

Minimize hours on the phone and get to a solution faster.

Live feed from the feeder, screen attachment, wind-sifter, and rear of the machine gives you complete visibility of your crusher’s operation.

This allows you to catch potential issues early and eliminate the risk of manual inspections in hazardous areas.

This camera shows you the screen deck and the return conveyor.

This camera shows you the feed hopper.

Optional rear view camera.

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.