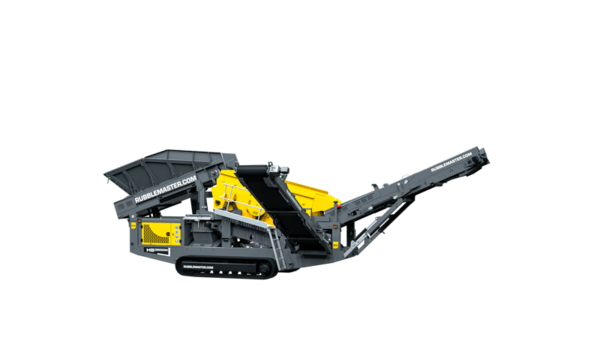

RM 70GO! 2.0

Compact Crusher

The Most Compact Professional Crusher to Produce Quality Aggregates

The RM 70GO! Compact Crusher is the full package in a small footprint. It features all the bells and whistles of a full-size crusher including an on-board screen and return conveyor for a closed-loop production, magnetic separator, and more. It is the ideal choice for smaller producers and those who want to start small, but grow fast.

Custom Crushing

Crush for others without competing with large crushing outfits.

On-Site Recycling

Crush your own materials on-site and save on trucking & disposal costs, and the purchase of new aggregates.

Aggregate Production

Produce your stockpile of spec material at a fraction of the cost of purchased aggregates. Ready to go, anytime.

A Compact Crusher, but Much Bigger Than You Think!

While many crushers are too big and expensive, and others are too small and can't meet spec, the RM 70GO! brings power, size, and aggregate quality into one affordable package so that you can make more money with your materials.

Up to 165 TPH

depending on materials

Adjustable Output Size

Produce anything from a ½"- to a 3"- material.

RM Release System

Unblock the crusher with the touch of a button on your radio remote control.

When Aggregate Quality Counts,

Count on RUBBLE MASTER

RUBBLE MASTER Compact Crushers are impact crushers that crush concrete, asphalt, and rock into base and sub-base materials. The on-board screen and return conveyor enable you to produce a spec product in a single pass.

Superior Gradation

Final aggregates are cuboid, gradable, and compact-able.

Thus ideal for base and sub-base materials.

Crush & Screen Simultaneously

Produce a commodity type screened product in a single pass.

Rebar Liberation & Segregation

Ideal for processing reinforced concrete.

Operate with The Touch of a Button

The operation of a RUBBLE MASTER crusher is unlike any other crusher. We focus on making machines less complex so that you can start crushing without lengthy training necessary because we believe everybody should be able to operate a crusher.

Intuitive and Simple

Less training necessary.

Radio Remote Operated

Run the crusher conveniently & safely from the cab.

One-Man-Operation

No need for a large crew.

Best of All You Can Trust Your Guys Around the Crusher

The RM 70GO! Compact Crusher is built from the ground up as a crusher for novice operators providing protection from injuries and protection of your investment.

Intelligent Machine

Sensors shut down the machine in case of an error to reduce the risk of injuries and machine damages.

Safety First Design

A 2-hand operation of hydraulics, safety pins, sensors, and guards reduce the risk of operator error and injury.

Ground Based Service

Low-mounted engine design makes light work of your dailies and keeps your feet on the ground.

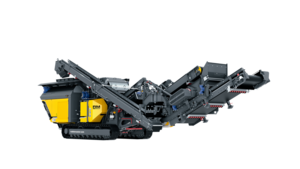

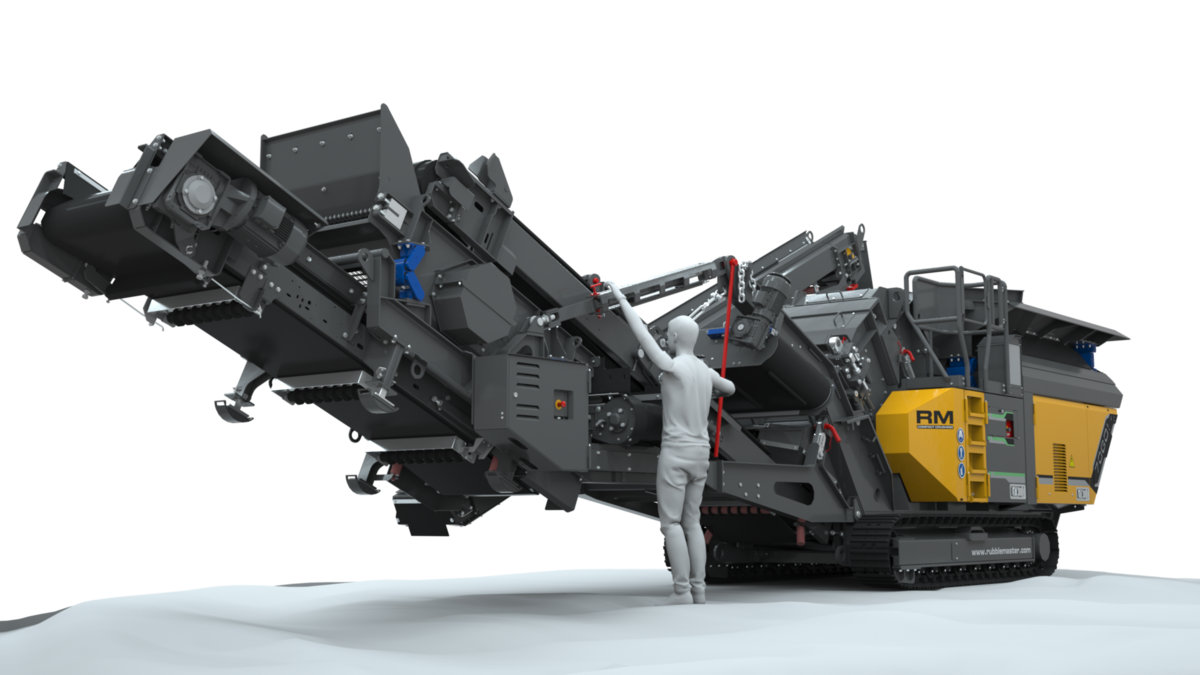

Go Anywhere, Anytime

RUBBLE MASTER always keeps mobility in mind so that you don’t have the hassle of burdensome permitting, escorts, and long setup times.

Easy Move

The RM 70GO! 2.0 is less than 8' wide and can be moved on the same trailer as your excavator.

Fast Setup

From trailer to crushing in 20 minutes without the need of special hand-tools.

Track & Crush

Crushed material must be stockpiled using a loader or conveyor. The RM 70GO! can windrow the material so you can run with minimal support equipment.

No Space, No Problem

If you think you have no space think twice. Our compact crushers are small enough to fit into tight yards, confined jobsites, and indoor jobsites. The ability to crush & track simultaneously doesn't require an additional wheel loader or stacking conveyor.

Small Footprint

One machine does it all. Crush, screen and separate rebar. No additional processing equipment needed.

Low Noise Emissions

Surprisingly quiet machine.

Low Feed Height

Easy to reach into the hopper with your excavator no matter how big or small your pile is.

Video Gallery

RM 70GO! 2.0 Specs

| Capacity | up to 150 tph up to 165 TPH |

| Inlet opening | 760 x 600 mm 30" x 23" |

| Ideal feed size | 450 mm 18 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 2 m³ 2.6 yd³ |

| Prescreen Grizzly (standard) | 1,000 x 700 39 x 28 |

| Drive | diesel-electric diesel-electric |

| Screen-box | 2,100 x 1,055 mm 3.5 x 7 ft |

| Transport dimension | 13,300 x 2,360 x 3,100 43'8" x 7'9" x 10'2" |

| Weight (no options) | 19,500 kg 42,990 lbs |

| Weight incl screen attachment | 24,200 kg 53,400 lbs |

Operating a RUBBLE MASTER Compact Crusher

is just…awesome.

Don’t just take our word for it.

„We are a one-stop shop for our customers. We demolish barns & silos, and we recycle on-site. Many of our clients can reuse the material. In the past, we had to call around to get someone to crush for us. If you depend on other people, you run into delays. That's why we purchased an RM 70GO! 2.0 Compact Crusher. By owning a machine, I have less troubles and can plan my jobs and rely on deadlines."

Josef Hamminger

Österreich

Talk to an Expert

Have a question? Fill out the form, and a material processing expert will be in touch with you as soon as possible.