Turn your materials into money

Dominate your job site with true support from people who care!

Turn your materials into money

Dominate your job site with true support from people who care!

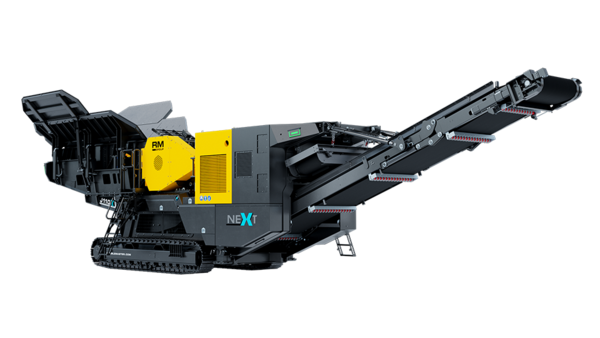

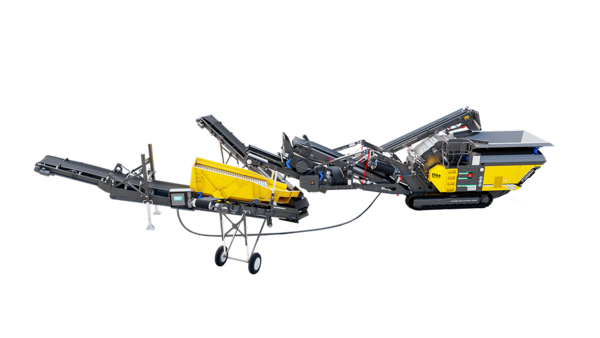

Maximize Production without Sacrificing Mobility

Simplify Your Operation

Minimize Safety Hazards and Trust Your Crew

If you don’t have a reliable material processing solution, you’re leaving money on the job.

Without easy to operate equipment you’re wasting man hours on repairing equipment, you are overwhelmed by the complexity, you are eating away at profit margin with outdated processes, and the growth of your company is being held back.

Ready for a NEW EXPERIENCE?

Minimize the stress. Maximize your profits.

Say Yes to More Jobs

Aggregate equipment is bulky, heavy, and difficult to move. RUBBLE MASTER machines are designed from scratch with mobility in mind, so you get the freedom to move anywhere and save transport costs.

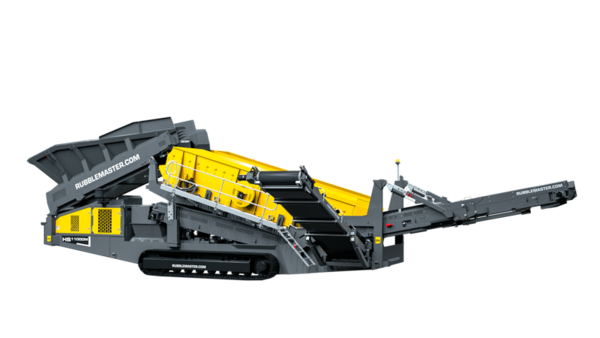

Astonishing Usability

Heavy equipment is hard to work on and getting more and more complex. RUBBLE MASTER builds crushers & screens that make material processing easier than ever. You can put any operator on your RUBBLE MASTER with confidence.

Cut Your Fuel Bill up to 25%

Operating costs affect your bottom line. RUBBLE MASTER's highly efficient diesel-electric drives provide the greatest fuel savings without sacrificing power, so you can make more money per ton.

Dominate your jobsite with more intelligence about your operation

Access machine telemetry and track tonnages conveniently from you home, office, or on the road.

Meet the highest environmental and emissions standards with RUBBLE MASTER’s electric drive solutions.

Uncertain times require sustainable solutions. At RUBBLE MASTER, we do not rely on old industry standards and traditional machine designs. Our goal is to use electrification and digitization to save operating costs, identify problems earlier, and minimize endless service calls. This is why we have been a leader in diesel-electric drives for over 30 years.

- Diesel-electric

- 100% electric

- Hybrid

RUBBLE MASTER Equipment is Available in More Than 110 Countries Worldwide.

Get The Equipment

We’ll pair you with a crushing and screening expert to help you choose the right machine that meets your needs and makes you money. We can even help you find the right financing for your new investment.

Get The Training

Once you get your new machine, we’ll train your staff onsite - your material, your machine. We design our machines for easy single-operator use, so your team will feel confident and safe using your RUBBLE MASTER crusher or screener.

Get It Done

Dominate the jobsite with machinery that holds up its end of the bargain. You’ll spend time getting the job done - not hauling material or fixing your machines. You’ll look forward to watching money coming out of your new machine every day you’re on the job.

Operating a RUBBLE MASTER

is just…awesome.

Don’t just take our word for it.

"RUBBLE MASTER crushers are incredibly flexible, easy to use, and extremely powerful. Even customers who have never worked with a crusher before can now easily recycle and save themselves and the environment the hassle of disposal."

Paul Fot

FOT Machinery

Germany

"In 2005 we bought our first RM crusher to launch our new line of business. In nearly 20 years with RUBBLE MASTER, one thing hasn’t changed - we have a family that seriously cares about us being successful in our business. That relationship still remains today and I believe it always will.”

Ron Garofalo

D.A.G. On-Site Crushing

United States

"I have about 12 RM machines and am very satisfied with their performance. The high quality of the final material produced by the RUBBLE MASTER impact crushers has really surprised me and helped me meet the requirements enormously.

Gabriel Meléndez

Grupo Indi

Mexico

Service Second to None.

Worldwide. For Life.

RUBBLE MASTER offers spare parts, service, and operator training so that you can get the most out of your investment. We are represented in over 110 countries worldwide and can help you quickly if you need it. This is for the entire life of your machine, regardless of hours and whether you bought the machine new or used.