Full Electric Mobile Material Processing Equipment for an Emission Free Operation

Electric Stationary and Hybrid Mobile Crushers to meet higher emission standards and reduce fuel & maintenance costs.

Electric Stationary and Hybrid Mobile Crushers to meet higher emission standards and reduce fuel & maintenance costs.

Electric Stationary and Hybrid Mobile Crushers to meet higher emission standards and reduce fuel & maintenance costs.

on hybrid crushers over diesel-electric direct drives.

More governments and cities are implementing laws to reduce emissions. Bid specs and subsidies are getting tied to electric drive systems. Environmentally sensitive areas, such as indoor material processing setups and inner-city job sites, render diesel-powered crushing and screening equipment undesirable. Additionally, more often than ever, you must find your profits in your existing cost structure.

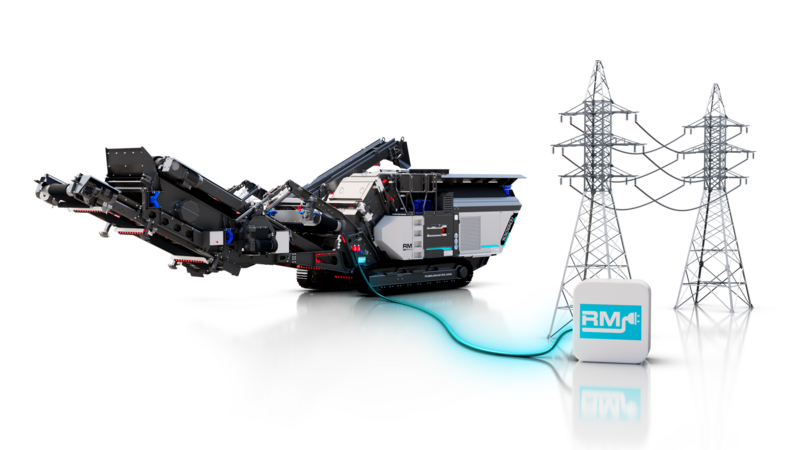

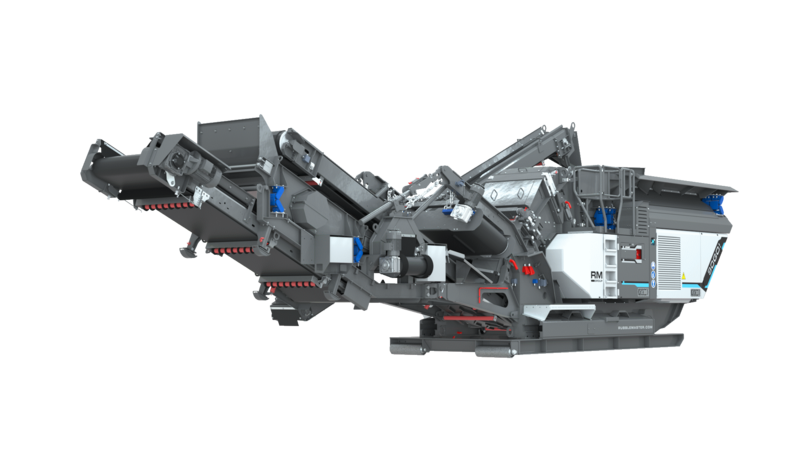

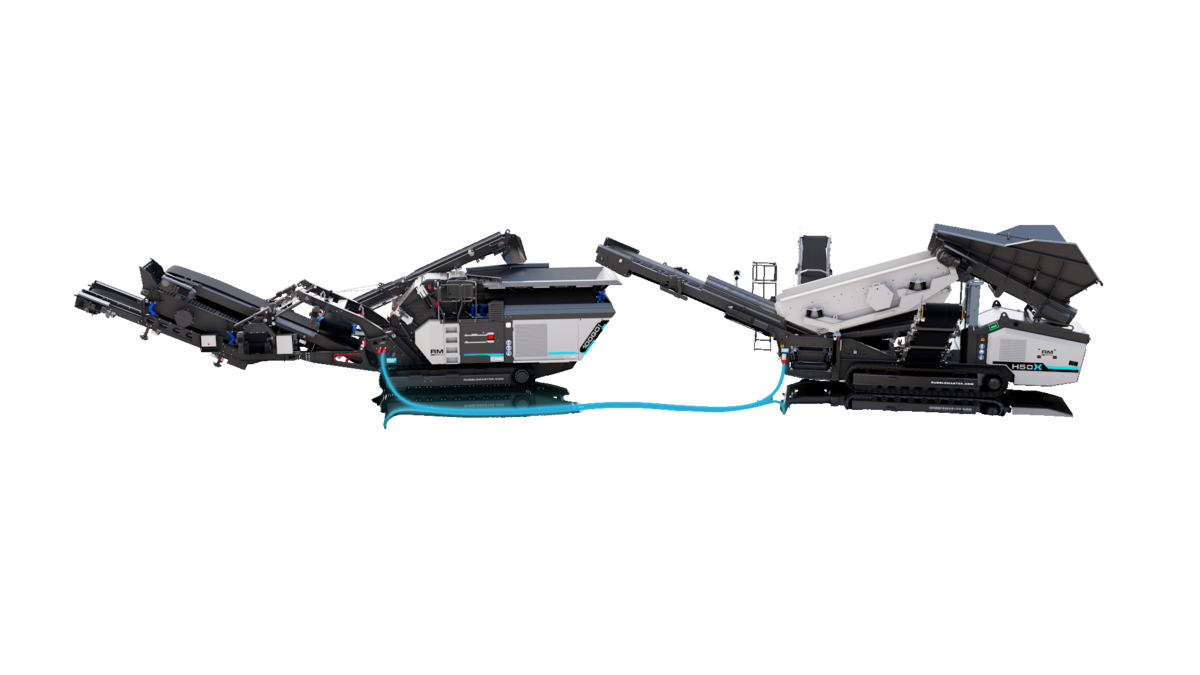

RUBBLE MASTER electric and hybrid crushers can be hooked to the grid or a generator. 100% electric crushers fit into an existing processing plant or job site with already available electric power. Hybrid crushers (diesel-electric crushers with optional grid hook-up) combine the benefits of an electric plant with the mobility of a diesel-powered mobile crusher. This means you can choose between operating the diesel engine or using grid power. In contrast to other systems, the diesel engine of the RM hybrid drive exclusively powers a generator, which subsequently powers all drives (including the crushing chamber or screen box) electrically.

The entire industry is moving towards electric. RUBBLE MASTER has used electric drives on mobile-tracked crushers for over 30 years. As true innovators in this domain, we don't Frankenstein hydraulic machines with electric hydraulic pumps. All drives are electric, ensuring maximum system efficiency and meeting the highest standards. This gives RUBBLE MASTER users the ultimate benefits of an electrified crushing & screening system.

Utilize surplus power to operate a compact screen attachment or electrified mobile screening plant. Best of all, this works with our diesel-electric direct drive crushers as well as hybrid crushers.

Save fuel and maintenance costs.

Only one emission-emitting engine.

Advanced machine-to-machine and machine-to-operator communication enables operators to control the crushing system efficiently.

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.