How to Minimize Crushing Noise Emissions on Your Jobsite

Reducing noise in crushing ensures compliance and creates a safer, quieter, and more efficient jobsite

Noise emissions on construction sites can be a significant challenge, especially when using equipment like crushers that handle heavy-duty tasks. Whether you’re working in an urban area, near residential zones, or in environmentally sensitive locations, minimizing noise emissions is critical to maintaining regulatory compliance, community relations, and worker safety. This article will explore practical strategies to reduce crushing noise emissions and create a more efficient, quieter jobsite.

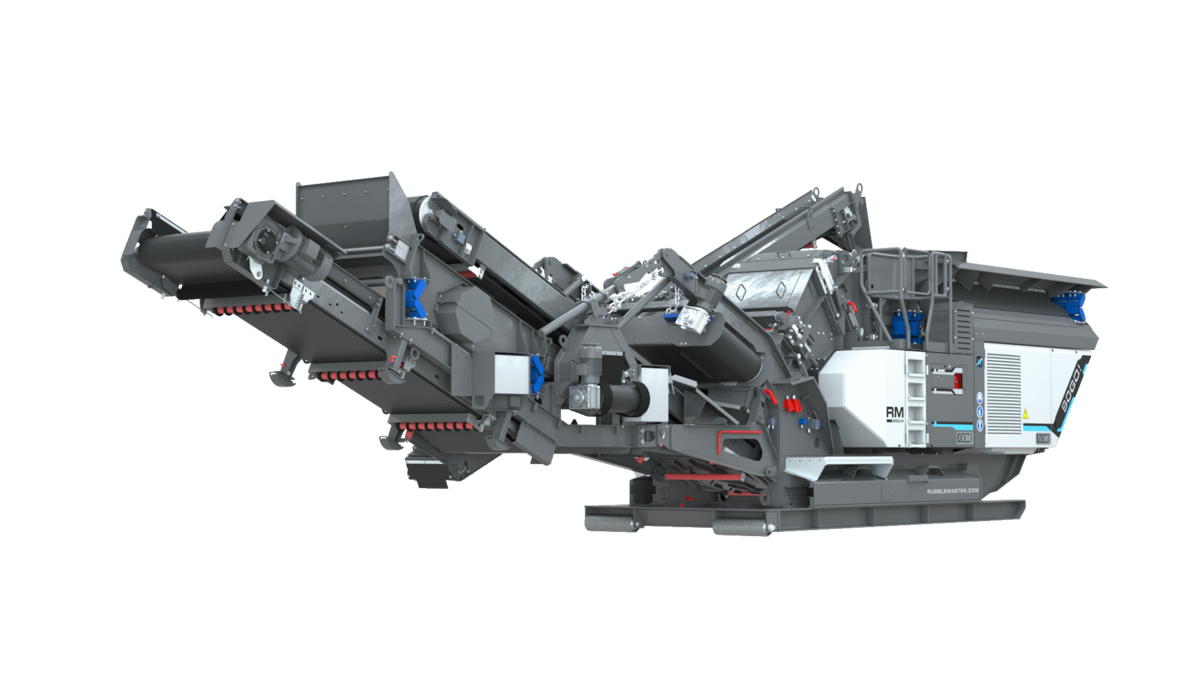

Investing in advanced, low-noise machinery is the most effective way to minimize noise emissions. Many modern crushers, like those from Rubble Master, are specifically engineered to operate at reduced decibel levels without sacrificing performance. Look for machines that feature:

Sound-dampening technology: Built-in insulation or enclosures to reduce operational noise.

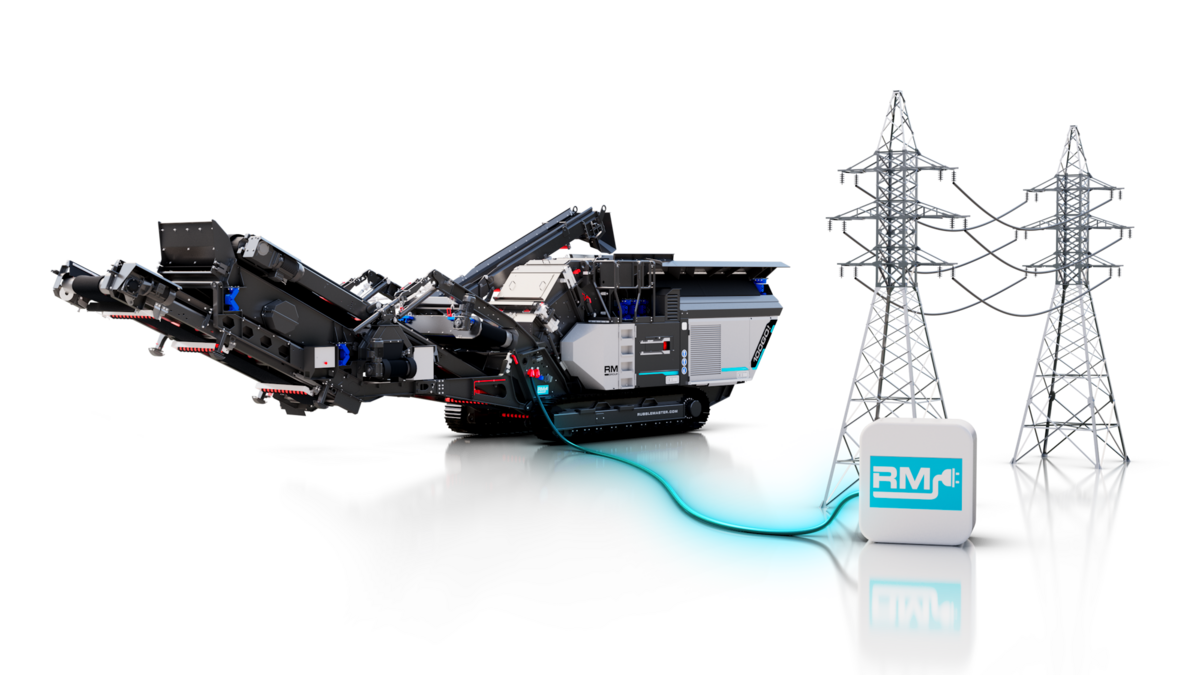

This can be improved further by upgrading your drivetrain to a full-electric crusher drive. This allows you to utilize grid power and shutting off the diesel-engine.

Hybrid Crushers give you the freedom to operate the diesel engine or utilize existing grid power while maintaining full mobility.

Electric crushers utilize the grid-power while sacrificing mobility. Those crushers are stationary or skid-mounted in nature.

Key Tip: Compare decibel ratings when purchasing or renting crushers to identify the quietest option available.

How you position and manage equipment on the jobsite can significantly impact noise levels. Consider these best practices:

Strategic placement: Position crushers away from noise-sensitive areas, such as residential buildings, schools, or hospitals. Use natural barriers like hills or constructed sound barriers to absorb noise.

Limit open spaces: Crushers should be operated in partially enclosed areas to contain noise. You can also shield your crushing operation with existing material stockpiles.

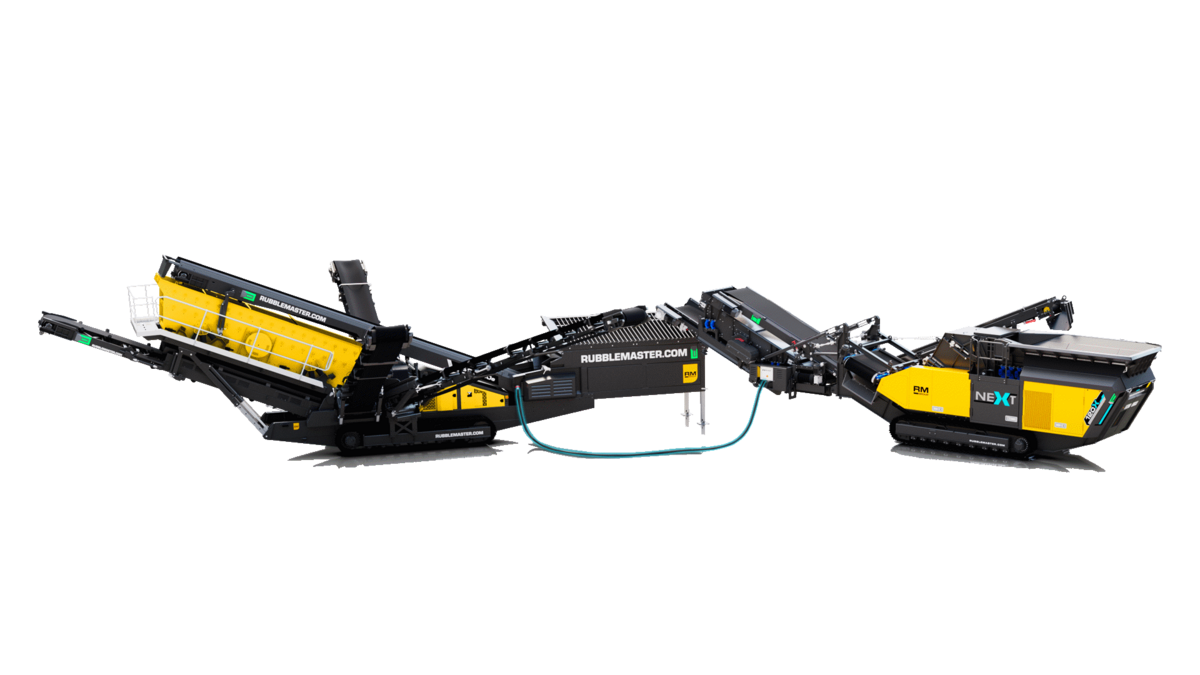

Minimize total equipment fleet noise: Use a tracked conveyor to stockpile material efficiently and avoid irritating noise from wheel loaders' back-up beeping.

Temporary or permanent sound barriers can be highly effective in reducing noise emissions. Options include:

Sound walls: Constructed wooden, metal, or acoustic barriers can shield noise-sensitive areas.

Minimizing crushing noise emissions is not just about meeting regulations – it’s about creating a safer, more efficient, and community-friendly jobsite. By investing in low-noise equipment, optimizing your jobsite layout, and adopting noise reduction strategies, you can set your projects up for success. For quieter and more effective crushing solutions, consider partnering with manufacturers like RUBBLE MASTER to take your operations to the next level.