How does a single toggle jaw crusher work?

How does a single toggle jaw crusher work?

Benefits of a Jaw Crusher

High Performance

& Low Costs Per Ton

Ideal for an initial reduction in size, jaw crushers take the brunt before feeding material into a cone crusher or impactor.

Multiple Applications

Jaw crushers crush a variety of natural materials efficiently, including soft & hard stones, highly abrasive rock, ore, and concrete with rebar.

Easy Maintenance

& Low Wear

Jaw ties and cheek plates last very long and can be changed easily and quickly.

A Single Toggle Jaw Crusher Works Like a Giant Nut Cracker

The jaw crusher, crucial for mobile operations, comprises a fixed jaw plate securely attached to the crusher mainframe, while a movable jaw plate is mounted onto a jawstock.

Cheek plates provide additional wear protection for the mainframe. Positioned in a V-shape, the two jaw plates create a narrowing space, known as the nip angle. An eccentric shaft, passing through the top of the jawstock and pivoting around a toggle plate at the lower half, generates an elliptical motion, facilitating efficient crushing.

Material undergoes compression between the jaw plates, gradually reducing in size within the crushing chamber until exiting at the bottom. Adjusting the CSS (closed side setting) between the fixed and moving jaw plates allows for precise control over the output size, ensuring versatile crushing capabilities for various applications.

Limitations Of A Jaw Crusher: Lack Of Fine Material

Typically, jaw crushers produce less fine material than impact crushers. The reduction ratio of a jaw is approx. 4 to 1. Fines are necessary to meet certain gradations and increase material compaction. This is the reason why a jaw crusher is predominenatly used as a primary crusher for an intial reduction in size or to produce a non-spec material.

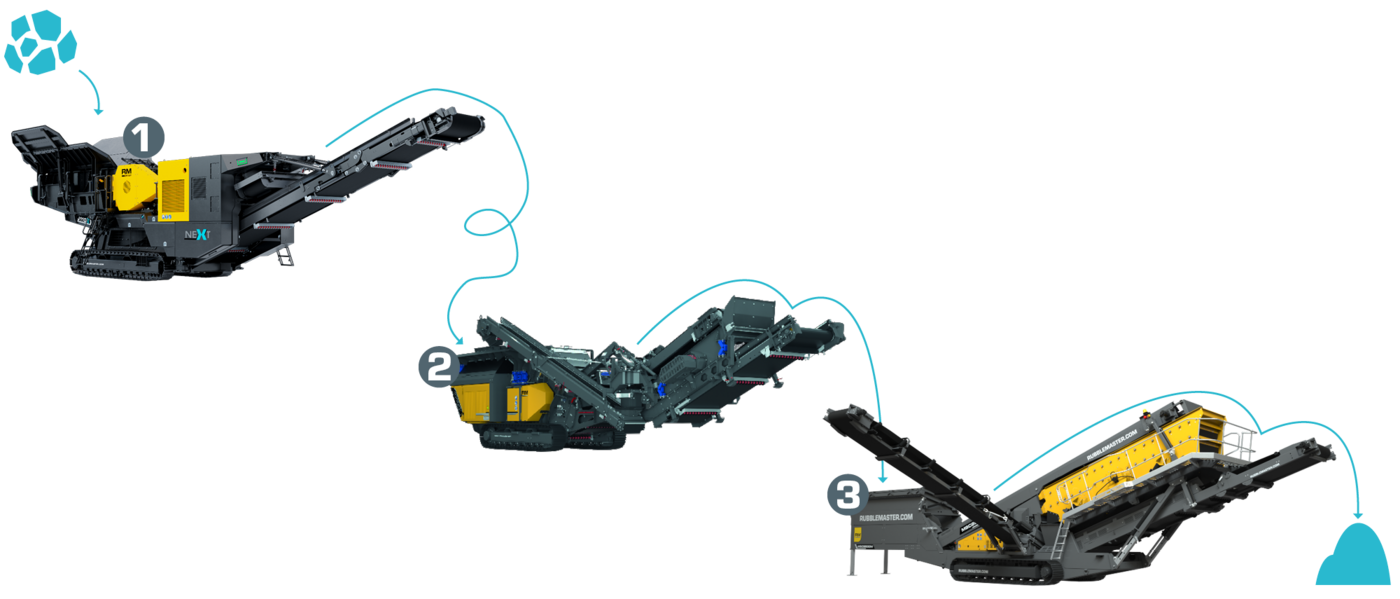

Single Toggle Jaw Crushers Take The Brunt In Combination With Other Crushers And Screens

Crusher trains are a combination of several mobile crushing and screening plants to achieve a high output of desired spec products. A common setup is a primary jaw crusher, followed by an impact crusher, feeding into an incline screen to split the aggregate into several fractions.

Primary crushing

A mobile jaw crusher makes an initial reduction in size.

Secondary crushing

A cone or impact crusher reduce the material further. This process yields also larger amounts of fines, grit, and dust.

Precision screening

A mobile incline screen or scalping screen split the aggregate into several fractions.

Large feed sizeX

The jaw crusher is fed with large and bony materials (e.g. blast rock).

Initial reduction in sizeX

The jaw crusher produces a 6-8"- material that is fed into a secondary crusher such as an impact crusher or cone crusher to further reduce the material in size.

Further reduction in size and incrase of fine materialX

A secondary crusher reduces the material further in size (e.g. 1"-).

Spec materialX

A mobile screening plant such as an incline screen split up the material in several fractions that meet spec.

Single Toggle Jaw Crushers are Easy to Run

Follow these simple rules to keep crushing

1. Maintain Cleanliness

For optimal performance of your equipment, it's crucial to keep an eye on the oil level regularly and ensure it stays uncontaminated.

When it's time for an oil change, be diligent in clearing away any dirt beforehand to prevent contaminating the fresh oil. Don't forget to maintain cleanliness by regularly cleaning the breather filters and replacing oil filters and seals.

At the end of each day, take the time to remove any dirt and debris from the crusher surfaces to keep everything running smoothly

2. Keep Up with Your Daily Maintenance

For top-notch performance, it's essential to inspect the jaw ties and cheek plates daily for signs of wear and ensure bolts are tight.

Keeping a close eye on your closed side setting is key to maintaining a consistent final product.

Don't forget to change out jaw ties promptly; excessive wear can hamper maximum utilization of your equipment. Stay ahead of the game by staying proactive with these maintenance tasks to keep your jaw crusher operating at its best.

3. Take Care of Your Feeding Behavior

For optimal performance, ensure your jaw crusher is fed with a mix of coarse and fine material. Feeding oversized material can lead to uneven wear, shortening the lifespan of your equipment.

Maintain a choke feed to maximize production and material reduction consistently.

Steer clear of trickle feeding, as it accelerates wear on the lower part of the jaw plates, diminishing their longevity.

Moreover, avoid overloading the hopper to enable the grizzly section to eliminate fines before crushing, preserving the efficiency of your crushing process. Stay proactive with these feeding strategies to enhance the productivity and longevity of your jaw crusher.

RM J110X

Mobile Jaw Crusher