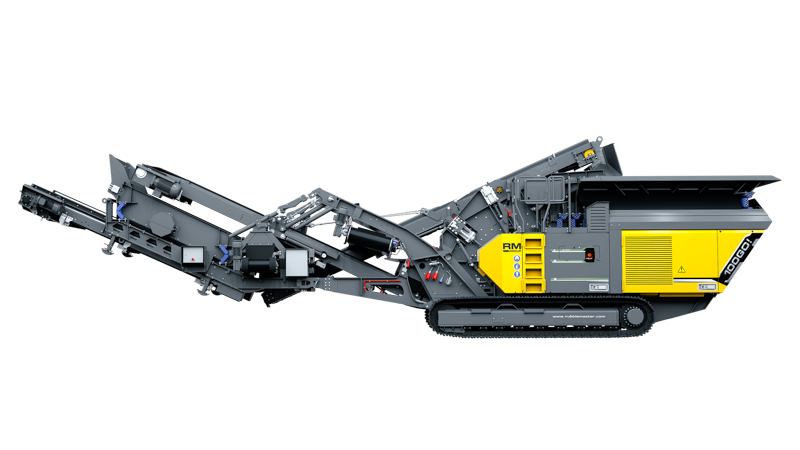

RM 100GO!

Tracked Impact Crusher

The Tracked Impact Crusher for Pros

When production counts, you can count on the RM 100GO! Tracked Impact Crusher. If you don’t have a reliable machine, you’re leaving money on the job. The high-performance impact crusher along with its simple & intuitive controls puts more product on the ground.

Performance

This powerful crusher weighs less than 75,000 lbs and can be mobilized easyily in most states and provinces.

Ease of Use

A new experience operating a tracked impact crusher. Common sense solutions make the hardest parts of crushing easy.

Safety

Build from the ground up with operator safety in mind so you can trust your guys around the machine.

Don't Get Fooled by Its Size. Our Tracked Impact Crusher Punches Over Its Weight Class.

For more than 30 years, we’ve designed and manufactured our crushers to deliver best-in-class performance without sacrificing mobility.

3 Crushing Stages on a

Single Impact Wall

Our proprietary impact crusher has proven time and time again to perform brilliantly in recycle and rock applications.

Maximum Reduction

The first crushing stage features toothed baffle plates for maximum reduction upon the first impact.

Cuboid Aggregates

Customers Want to Buy

The powerful impact crusher provides multiple setting to adjust your final gradation so you hit spec guaranteed.

Built to Keep You Crushing Longer

We understand that if your crusher is down your crew is down and you are bleeding money. That's why all components come out of "one mold" to ensure a smooth material flow, so you can minimize downtime and maximize profits.

Self-Regulating Feeder

Performance peaks can stall an impact crusher. The self-regulating feeder adjusts the speed, so that you process your material smoothly and keep crushing.

Jam Detection & Overload Protection

Material blockages can result in serious belt damage. RUBBLE MASTER tracked impact crushers shut down the operation automatically to reduce the risk of damages.

Fast Adjustments

Every minute you spend idling costs you. This is why, we designed everything for efficiency, from changing wear parts to adjusting your crusher geometry.

Removes Blockages by The Touch of a Button with the RM Release System.

Materials don't come in convenient sizes or shapes. In case the material doesn't fall into the action radius of the impactor you can open the apron via the radio remote control so the material gets caught by the rotor and you keep crushing.

We Make the Most Burdensome Parts of Crushing Easy.

The operation of a RUBBLE MASTER compact impact crusher is unlike any other crusher. We focus on making machines less complex so that you can start crushing without the lengthy training necessary because we believe everybody should be able to operate a crusher.

Simple & Intuitive

We’ve taken the complexity out of mobile crushers. Because “safety and ease of use” is our top priority!

Radio Remote Operated

Run the crusher conveniently & safely from the cab.

One-Man-Operation

No need for a large crew or specilized knowledge.

Get More Clarity. Make Better Decisions.

The RM XSMART telemetry app gives you access to more data and allows you to track tonnages (only with optional belt scales) conveniently form your cell phone or computer. Optimize your processes and get more done in a day.

Best of All you Can Trust Your Guys Around the Machine.

The RM 100GO! Tracked Impact Crusher is built from the ground up as a crusher for novice operators providing protection from injuries and protection of your investment.

Ground Based Service

Low-mounted engine design makes light work of your dailies and keeps your feet on the ground.

Meet The Highest

Safety Standards

A 2-hand operation of hydraulics, safety pins, sensors, and guards reduce the risk of operator error and injury.

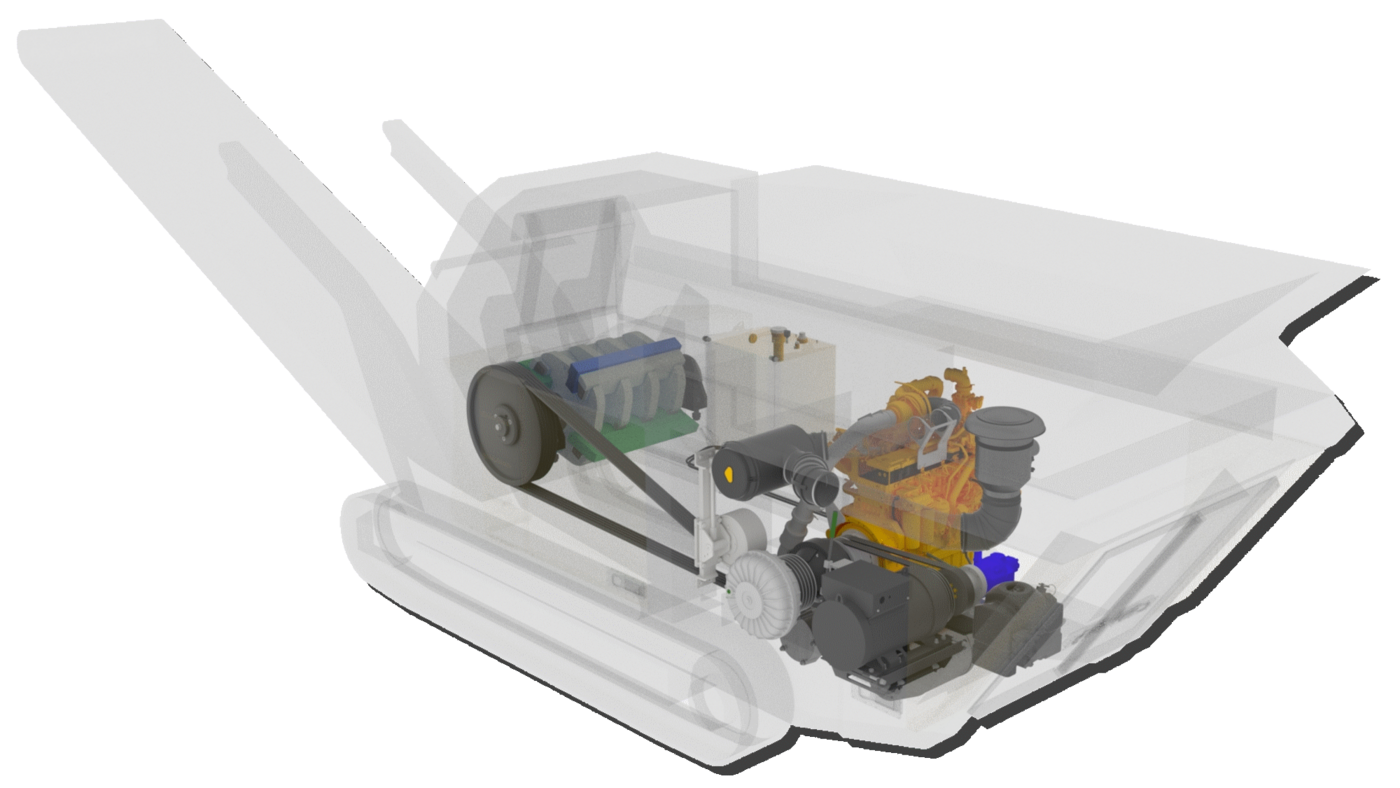

Save Up to 30% in Fuel With our Diesel-Electric Direct Drive

compared to traditional diesel-hydraulic tracked impact crushers

Since 1991 We are the Experts in Electric Crusher Drives

We utilize the most reliable electric motors and feature refined controls.

Works Well in Extreme Temperatures

No heating up of hydraulics in winter and no overheating in summer.

Save big on hydraulic fluids

Our small hydraulic system (30 gal) is used for auxiliary functions only. Say goodbye to bursting hoses, leaks, and DEP citations.

Direct driveX

The rotor is directly driven by the diesel engine via a manual twin-disc clutch and hydraulic coupling for a soft start.

GeneratorX

The generator produces the electric power to run conveyor belts, feeder, and shaker motors.

Small hydraulic pumpX

The small hydraulic system is needed to operate auxiliary functions such as cylinders to setup the machine and adjust the crusher geometry as well as tracking the machine.

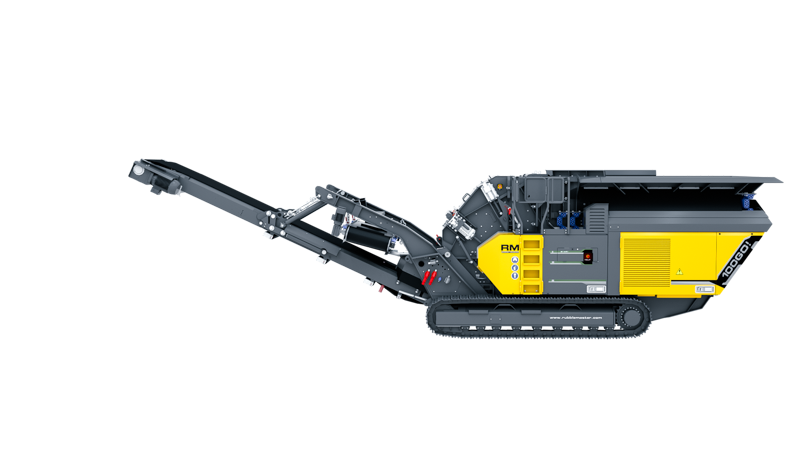

Go Anywhere, Anytime

Many crushers in this class require special permits and more than one load to float. The RM 100GO! tracked impact crusher weighs approx 75,000 lbs and is not considered a super-load in many states. This gives you the freedom to do more jobs faster.

Precision Movements

The refined controls allow for exact maneouvers on the job and while loading.

15 Minutes From Trailer to Crushing

A single operator can get the crusher ready without the need of special hand tools.

Fits on Most Trailers

Use the same trailer you use for your excavator. Single move.

Perfect for Any Jobsite

Contractors are facing thinner margins due to an increase in smaller jobsites, neighbors’ complaints, and longer trucking times. One versatile RUBBLE MASTER machine can crush any on-site material volume, from just a few hundred tons to very high volumes, virtually putting money back into your pocket.

Bar None - The Quietest Crusher

Suprisingly quiet crushing operation.

Small Footprint

Ideal for on-site crushing where there is little room for setting up large crushing spreads.

Track & Crush Simultaneously

Eliminates the need for an additional wheel loader or stacking conveyor on-site.

Video Gallery

RM 100GO! Specs

| Capacity | 250 tph 275 TPH |

| Inlet opening | 950 x 700 mm 37" x 28" |

| Ideal feed size | 560 mm 22 " |

| Crusher unit | 4-bar rotor 4-bar rotor |

| Feed unit | 3.3 m³ 4.3 yd³ |

| Feed height | 3,000 mm 9' 10" |

| Prescreen Grizzly (standard) | 1,500 x 900 mm 4'11" x 2'11" |

| Screen-box | 1,300 x 3,000 mm 4 x 10 ft |

| Engine | 242 kW 325 HP |

| Drive | diesel-electric diesel-electric |

| Transport dimension | 14,700 x 2,860 x 3,155 mm 48'3" x 9'5" x 10'5" |

| Weight | 33,600 kg 74,500 lbs |

RM XSMART Telemetry

RM XSMART Telemetry

|

Operating a RUBBLE MASTER

is just…awesome.

Don’t just take our word for it.

"Out of all the crushers we have tried the RUBBLE MASTER puts out the best product around. This machine is putting out product people are waiting in line to buy".

Joe Maggio, Joe Maggio Construction

"The main reason for RUBBLE MASTER is customer service. The second reason that machine does a great job crushing. The third reason my guys understand the machine."

Danny Salomon, Broadway Recycling

Purchase Your Crusher the Easy Way

RUBBLE MASTER Finance provides leasing and financing solutions to keep your business productive, efficient, and competitive within the industry by offering a suite of financing products that can be customized to meet the most complex budgetary needs

Talk to an Expert

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing & screening experts and work closely with contractors and aggregate producers world-wide.